TM 5-4210-233-14&P-2

6-65. AIR COMPRESSOR-Continued

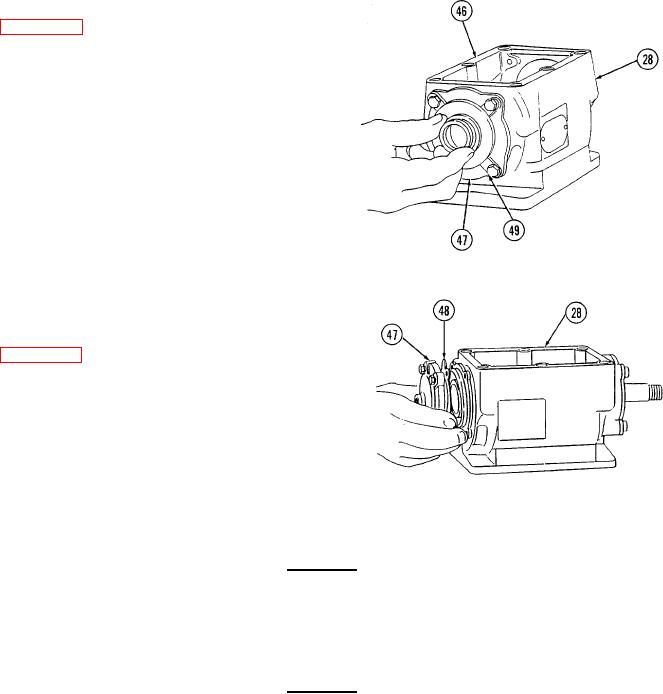

(1) Press new oil seal (46) into front bearing cap

(47). Use seal retainer compound (Item 6,

Appendix E) on seal's outer rim. Spring side

of seal must face inside of crankcase when

installed. Seal case should be flush to .005

inch (.13 mm) below front of cap.

(2) Crankshaft (42) should be installed in

crankcase (28) before front (47) or rear (40)

end caps are installed. Ball bearings should

already be pressed on crankshaft. Press

crankshaft and bearing assembly into

crankcase. Be sure that both front and rear

bearings protrude an equal amount from

each end of crankcase. Rotate crankshaft

to be sure it turns freely.

(3) Place new gasket (48) on crankcase front cap

mating surface.

(4) Apply small amount of engine oil (item 10,

Appendix E) to crankshaft seal (46). Slide front

bearing cap (47) over crankshaft end. Do not

damage oil seal.

(5) Place new gasket on rear end cap (40) mating

surface. Install spring or bowed washer in end

cap. Outer diameter of bowed washer must

contact bottom of hole in end cap. Install new

seal in end cap. Lubricate seal with oil. Install

end cap making sure seal and spring or bowed

washer do not fall out.

CAUTION

Do not overtighten bolts.

(6) Pull both front and rear bearing caps into position by alternately tightening four attaching bolts (39

and 49). Torque to 120 to 160 in. Ibs (13.6 to 18.1 Nm).

CAUTION

Crankshaft should revolve freely after assembling cap.

6-393