TM 5-4210-233-14&P-2

6-65. AIR COMPRESSOR - Continued

(27)

Check the seal and spring or bowed washer in rear bearing cap.

(a)

Check wear of seal where it contacts crankshaft. Seal must be replaced if grooved more than

0.005 in. (0.13 mm). Measure outside diameter of seal ring. If diameter is not .635 to .636 in.

(16.13 to 16.15 mm) the seal ring must be replaced.

(b) Check oil seal spring or bowed washer for wear. if worn, replace.

(28)

Examine crankcase for cracks and damage to gasket surfaces. Replace if necessary.

(29)

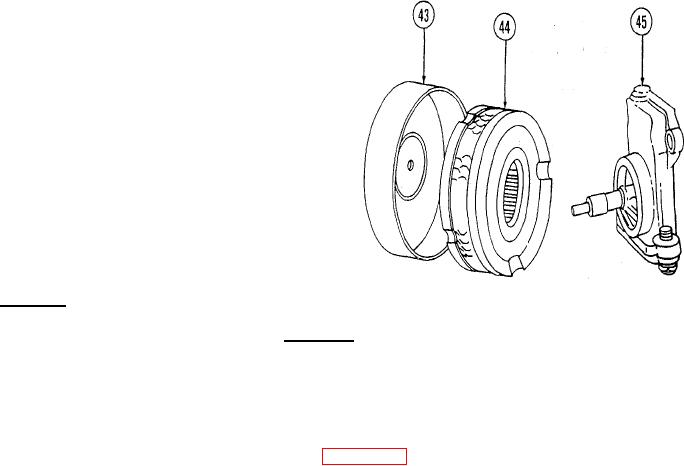

Unscrew air cleaner assembly cover (43) and

remove the air cleaner element (44). Replace

element if dirty, crushed or damaged.

(30) Replace air cleaner cover (43) or base (45) if

either is bent, crushed or damaged.

c.

Assembly.

CAUTION

Do not attempt to force any components du ring assembly. Investigate the problem

if assembly is not smooth and force free.

NOTE

block bores with engine oil (Item 1 0, Appendix E) before reassembly.

NOTE

Special parts, in addition to standard parts, are available for overhauling each

compressor. Included are 0.020 in. (.51 mm) oversize pistons and rings, cylinder

blocks with 0.020 in. (.51 mm) oversize cylinder bores, and 0.01 0 and 0.020 in.

(.255 and .51 mm) undersize bearing inserts.

6-392