TM 5-4210-233-14&P-2

6-65. AIR COMPRESSOR - Continued

NOTE

Clearance between rings and ring grooves gap must be .0015 to .0045 in.

(.0381 to .1 143 mm) for compression rings and .0005 to .0045 in. (.01 27 to

.1 143 mm) for oil ring. Ring gap must be .007 to .017 in. (.178 to .432 mm)

for compression rings and .015 to .055 in. (.381 to 1.341 mm) for oil ring. If

clearance or gaps are not within these limits, new rings must be installed.

Whenever a complete compressor teardown is accomplished, new rings are

recommended.

(19) Examine connecting rod bearing inserts for scoring, pitting or visible wear. Check fit of rod bearings on

crankshaft journals. Clearance between bearing and crankshaft journals must be between 0.005 and

0.0021 in. (.127 and .053 mm). If damage is evident or clearance does not meet the specified

dimensions new inserts must be installed.

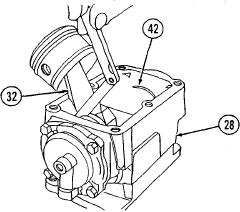

(20) Check clearance between side of connecting rod

bearing cap and crankshaft (42). If clearance exceeds

0.010 in. (.254 mm), new rod and bearing cap must be

installed. Connecting rod journal width should be 1.365

to 1.367 in. (34.67 to 34.72 mm).

NOTE

The connecting rod and rod bearing

cap must be replaced as a unit.

(21) Examine cylinder blocks (27) for cracks. Replace it

damaged.

(22) Examine cylinder bores for scatches, scoring and pitting. Check bores for out-of-round and taper. If

out-of-round more than 0.0005 in. (.01 27 mm) or tapered more than 0.001 in. (.0254 mm) from top to

bottom of bore, block must be rebored or honed oversize, or replaced with new cylinder block.

(23) A bent or twisted crankshaft (42) cannot be repaired. If connecting rod journals are scored beyond

repair or worn beyond 1.850 to 1.855 in. (46.99 to 47.12 mm), replace with a new crankshaft or regrind

journals. Service insert bearings are available at 0.01 0 and 0.020 in. (0.25 mm and 0.51 mm)

undersize.

(24) Thread, keyway, and ail ground and machined surfaces must not be mutilated or worn.

(25) Examine ball bearings for worn or damaged balls; rotate bearing by hand to detect roughness. If wear,

roughness or damage is evident, bearing must be replaced.

(26) Examine crankshaft front and rear bearing caps and replace if worn or cracked.

6-391