TM 5-4210-233-14&P-2

6-65. AIR COMPRESSOR - Continued

(10) Examine exhaust valve seat (1 6) for damage and wear. Measure valve guide diameter and distance

from top of valve seat to valve stop. Exhaust valve guide diameter should be 1 .145 to 1 .151 in. (29.08

to 29.24 mm). Top of valve seat to valve stop should be .1 25 to .128 in. (3.18 to 3.25 mm).

(11) Examine exhaust valve stop (19A) for damage, looseness or wear. Measure distance from valve end of

stop to surface on which spring sets. If the exhaust valve stop is loosen, worn, damaged or distance

from valve stop surface to spring seating surface is not .72 to .74 in. (18.3 to 18.8 mm), head assembly

must be replaced.

(12) Examine unloader seal bore diameters for scoring or pitting. Check unloader pins (1 1) for damage.

Measure length of unloader pins, which should be 1.850 to 1.854 in. (46.99 to 47.09 mm).

(13) Check unloader springs (12) for loads at specified heights. Unloader spring load should be 3.38 to 4.18

Ibs (1.53 to 1.89 kg) at .395 in. (10 mm).

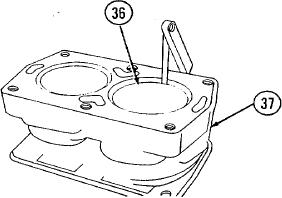

(14) Examine pistons (33) for scoring, cracks or other damage. Replace as needed.

(15) Measure the outside diameter at a 90 degree angle to the piston pin bore. Compare this measurement

with diameter of the cylinder bore. Piston diameter (below compression rings) should be 2.744 to 2.745

in. (69.70 to 69.72 mm) and cylinder bore diameter should be 2.7495 to 2.7500 in. (69.84 to 69.85

mm). Piston to bore clearance should not exceed .008 inches (0.20 mm). If clearance exceeds .008

inches (0.20 mm) replace the pistons. The block must be replaced or bored oversize to 0.020 inches

(.508 mm). Oversize pistons at 0.020 inches (.508 mm) are available.

NOTE

When measuring the outside piston diameter make sure the micrometer is at a 90

degree angle to the piston pin bore. This will permit a correct measurement.

(16) Check piston pins (35) for wear. Piston pins that have a variation in diameter of more than .003 inches

(.076 mm) must be replaced.

(17) Check fit of piston pin (35) and connecting rod (32). Pin should be a slip fit in piston and rod. Piston pin

bore in piston should be .5615 to .5618 in. (14.26 to 14.27 mm) and piston pin diameter should be

.5618 to .5620 in. (14.27 to 14.275 mm). Piston pin bore in connecting rod should be .5622 to .5624 in.

(14.28 to 14.285 mm). Visually check for worm or damaged areas and replace parts as required or

replace with complete piston and rod assembly. Connecting rod and rod bearing cap must be replaced

as a unit.

(18) Check fit of compression and oil rings in piston ring grooves.

Place rings in piston ring grooves and measure side

clearance. Place rings in cylinder bores and measure gap.

6-390