TM 5-4210-233-14&P-2

6-29. MAIN BEARINGS AND CRANKSHAFT

This task covers:

a.

Removal

d.

Assembly

b.

Disassembly

e.

Installation

c.

Cleaning and Inspection

f.

Follow-on Maintenance

TOOLS REQUIRED

PERSONNEL REQUIRED

Tool Kit, General Mechanics, Automotive

2

(Appendix B, Section III, Item 1)

EQUIPMENT CONDITION

Shop Equipment, Automotive

Engine Turned Upside Down on Engine Stand

Maintenance and Repair

Oil Pump Removed (see para 6-46.)

(Appendix B, Section III, Item 4)

Crankshaft Cover and Front Seal Removed

(see para 6-27.)

Set, Dial Indicator (Appendix B, Section III, Item 32)

Flywheel Housing and Rear Oil Seal Removed

(see para 6-31.)

MATERIALS/PARTS REQUIRED

Idler Gear Removed (see para 6-35.)

Compound, International No. 2 (Item 37, Appendix E)

Pistons, Connecting Rods, and Liners Removed

Oil, fuel, diesel (Item 41, Appendix E)

(see para 6-32.)

Tags, identification (Item 32, Appendix E)

Oil, lubricating (Item 10, Appendix E)

Cloth, crocus, abrasive (Item 34, Appendix E)

Cloth, cleaning, low-lint (Item 42, Appendix E)

Gauge, plastic (Item 43, Appendix E)

a.

Removal.

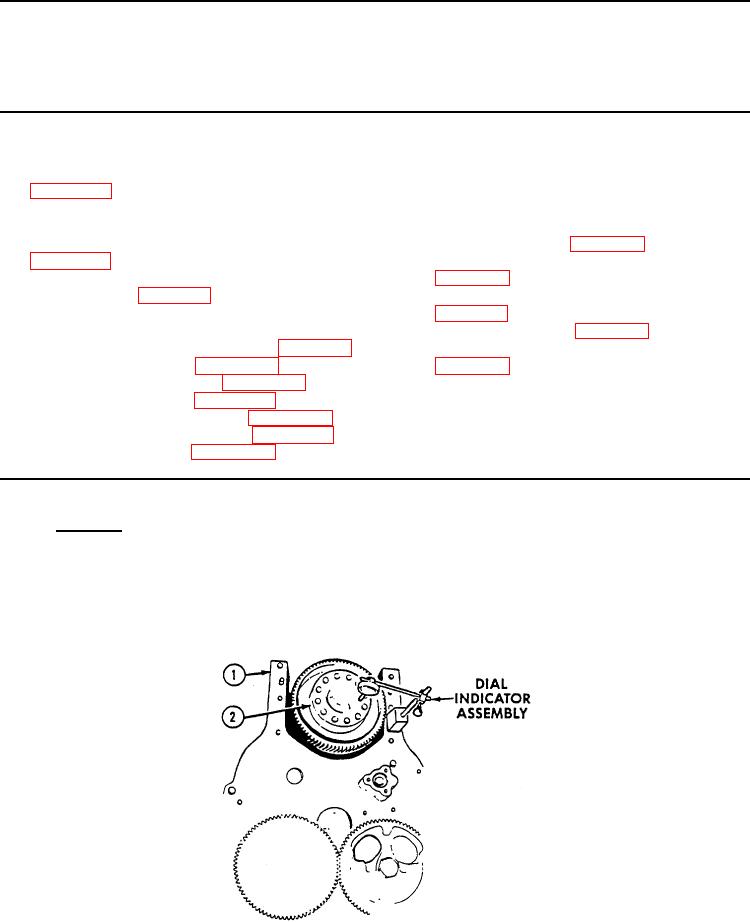

(1) Install dial indicator on engine block (1) and push crankshaft (2) towards gage with pry bar while

adjusting dial indicator to zero.

(2) Note end play while another person removes pry bar and forces crankshaft (2) in opposite direction.

Normal end play is .004 to .011" (.102 to .279 mm) with a maximum of .018" (.457 mm).

6-141