TM 5-4210-233-14&P-2

6-67. BRAKE DRUMS

This task covers:

a. Repair

TOOLS REQUIRED:

EQUIPMENT CONDITION

Tool Kit, General Mechanics, Automotive

Brake Drums Removed (see para 5-37.)

(Appendix B, Section III, Item 1)

MATERIALS/PARTS REQUIRED:

Solvent, Dry Cleaning (Item 3, Appendix E)

Crocus Cloth (Item 34, Appendix E)

a.

Repair.

WARNING

Dry cleaning solvent P-D-680 is

potentially dangerous.

Avoid

repeated and prolonged breathing

of vapors and skin contact with the

liquid.

Do not use near open

flame, arcing equipment or other

ignition sources. Always wear eye

protection and protective clothing.

The flash point of P-D-680 is 100

to 138 deg. F (38 to 59 deg. C).

(1) Clean brake drum with dry cleaning solvent (Item 3,

(2) Check brake drum for wear, cracks or damage. Replace brake drum if damaged beyond repair.

NOTE

Slight scoring conditions can be corrected by polishing with

crocus cloth (Item 34, Appendix E). Heavy scoring and out-of-

round conditions require turning brake drum on a refinishing

lathe.

Whenever the drum on one side of the axle is refinished, the

other drum on the same axle must be turned to the same size.

(3) Check inner brake surface of drum for heat checking, scoring or warpage.

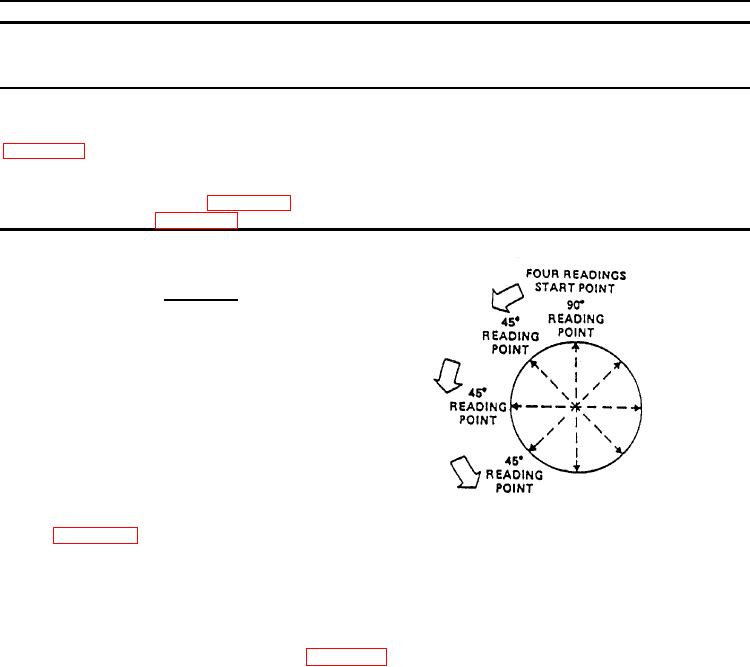

(4) Using micrometer, check inside of brake drum for out-of-round or tapered wear.

(5) Record each reading. The maximum difference between the four readings cannot exceed 0.006

inch (0.1524 mm). Drums with out-of-round exceeding limits must be turned.

6-400