TM 5-4210-233-14&P-2

6-60. THIRD CLUTCH AND CENTER SUPPORT HOUSING - Continued

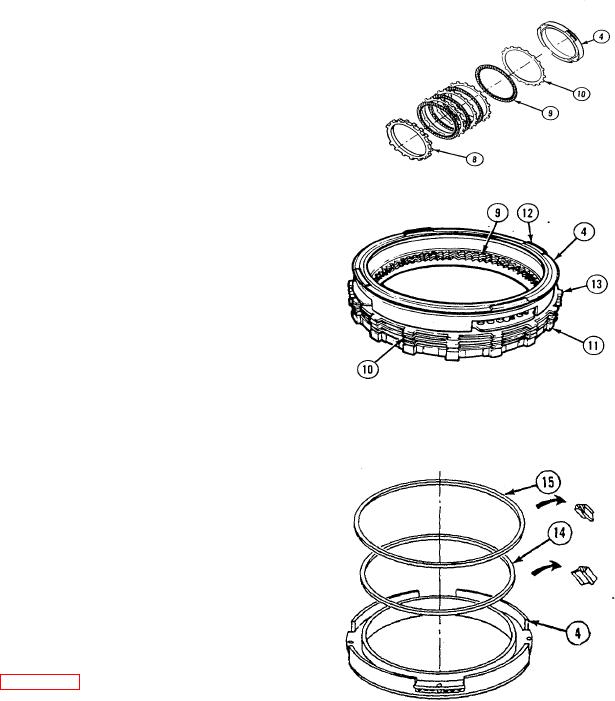

(8)

Place back plate (8) on flat surface

of press.

(9)

Stack eight clutch plates (9 and 10)

on back plate (8), starting with

friction plate (9) and alternating

with steel plate (10).

(10)

Place third clutch piston (4) on top of

clutch plates (9 and 10).

(11)

Press evenly on third clutch piston

(4) with 100 psi (689.5 kPa).

(12)

Measure distance from base of

clutch pack (11) to thrust pad (12).

(13)

Clutch pack thickness must be 3.010

to 3.042 in. (76.45 to 77.26 mm).

Replace clutch plates (9

and 1 0) as needed to ensure proper clutch pack thickness.

(14)

Measure thickness of one tang (13)

on each of four steel plates (1 0).

(a) If steel plate measures 0.1 16 to

0.123 in. (2.95 to 3.12 mm) steel

plate is thick.

(b) If steel plate measures 0.099 to

0.106 in. (2.51 to 2.69 mm) steel

plate is thin.

(15)

Repeat steps (8) through (13) to

recheck clutch pack thickness.

(16)

Remove clutch pack (11) from press.

(17)

Apply lubricating oil (Item 10,

Appendix E) to new inner seal ring

(14) and new outer seal ring (15).

(18)

Install new inner seal ring (14) and

new outer seal ring (15) on third

clutch piston (4) with lips facing

down.

6-353