TM 5-4210-233-14&P-2

6-32. PISTON, CONNECTING ROD AND LINER - Continued

(18)

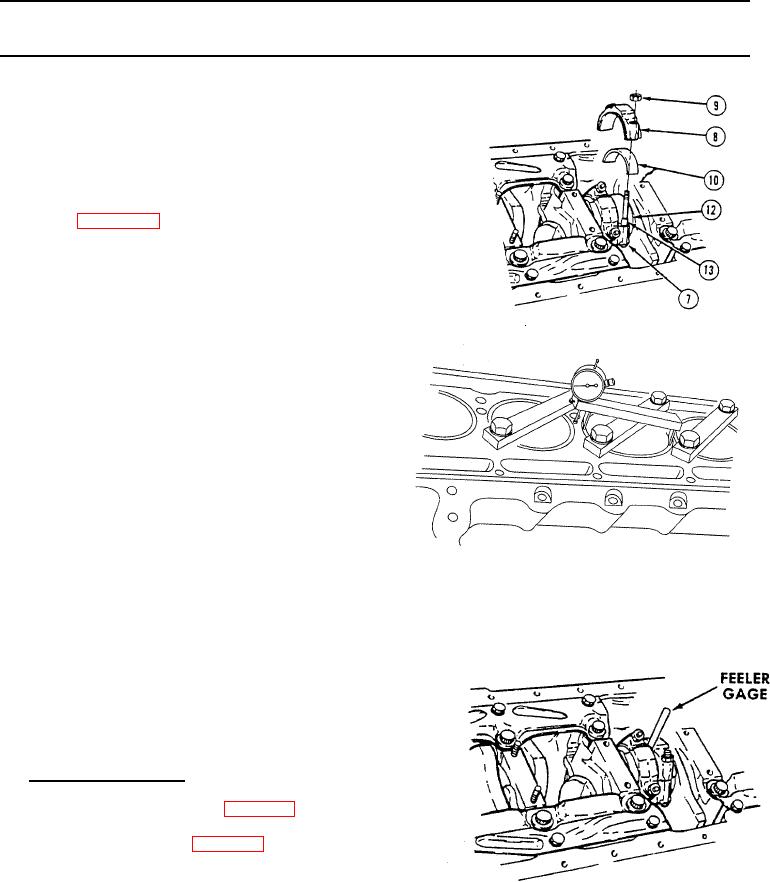

Seat connecting rod firmly on crankshaft journal (12).

(19)

Install cap (8) and bearing shell (10) over studs (13).

(20)

Install two nuts (9) and tighten to 60 to 70 Ib-ft (81 to

95 N.m).

(21)

Clamp the liner in place with hold-down clamp

(Appendix B, Section 111, Item 46) and tighten the two

bolts evenly.

(22)

Measure the distance from the top of the liner to the

top of the block with a dial indicator. The liner flange

must be .0418" to .0482" (1.062 to 1.22 mm) below

the surface of the block. However,

even though all of the liners are within

these specifications, there must not

be over .0015" (.038 mm) difference

between any two adjacent liners

when measured along the cylinder

longitudinal centerline. If the above

limits are not met, install a different

thickness insert, install the liner in

another cylinder bore and recheck, or

use a new cylinder liner.

(23)

Matchmark the liner and the cylinder

block with a felt pen so the liner may

be reinstalled in the same position in

the same block bore. Place the

matchmarks on the side opposite the

camshaft. Remove the hold-down

clamp and the cylinder liner. Do not

remove the liner insert.

(24)

Using feeler gauge, check that clearance between

each connecting rod attached to same crankshaft

journal is 0.008 to 0.01 6 in. (0.2 to 0.4 mm).

c.

Follow-on Maintenance.

(1) Install cylinder head (see para 6-13.).

(2) Install oil pump (see para 6-46.).

(3) Install oil pan (see para 5-27.).

(4) Remove engine from engine stand.

6-182