TM 5-4210-233-14&P-2

6-33. PISTON REPAIR - Continued

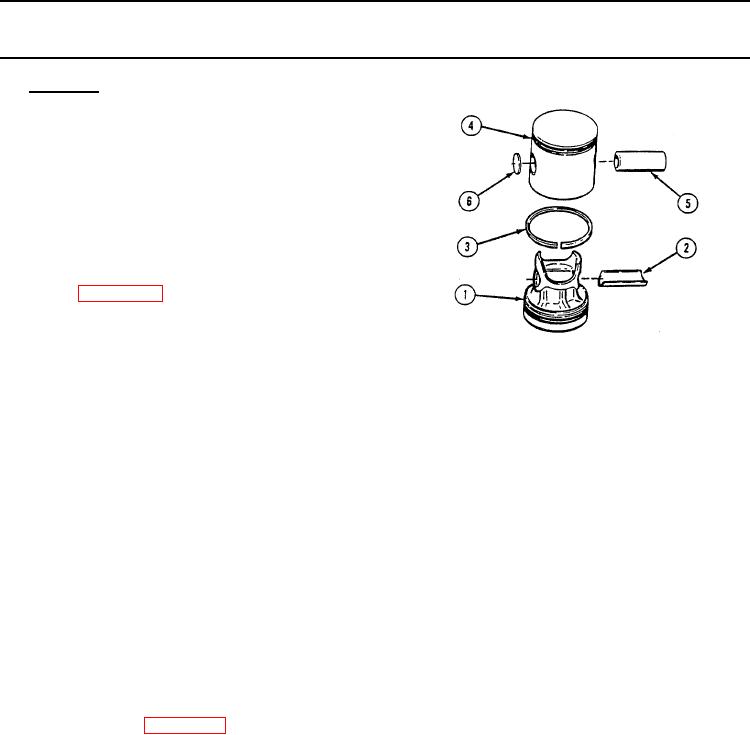

c.

Assembly.

NOTE

Be sure to align all match marks.

(1) Place piston crown (1) top end down, on work

bench.

(2) Install piston pin bearing (2).

(3) Coat metal seal ring (3) with lubricating oil (Item

10, Appendix E).

(4) Install metal seal ring (3) on piston crown (1).

Beveled side must face toward bottom of piston

crown (1).

(5) Rotate metal seal ring (3) fully around piston crown (1) and be sure it turns freely with no sticking

or binding.

(6) Compress metal seal ring (3) and push piston skirt (4) down into position on piston crown (1).

(7) Hold piston crown (1) and spin piston skirt (4). Piston skirt (4) must turn freely with no binding.

(8) Coat piston pin (5) with lubricating oil.

(9) Line up hole in piston skirt (4) with hole in piston crown (1).

(10) Install piston pin (5) with threaded holes toward bottom of piston skirt (4).

NOTE

Retainers must be seated fully and evenly in piston

skirt.

(11) Install piston pin retainers (6) in piston skirt (4) at each side of piston pin (5) using piston pin

retainer tool (Appendix B, Section 111, Item 47): install until they bottom out.

(12) Using leak detector, apply 1O-in. (254 mm) of vacuum to each piston pin retainer (6). There should

be no loss of pressure.

6-187