TM 5-4210-233-14&P-2

6-29. MAIN BEARINGS AND CRANKSHAFT-Continued

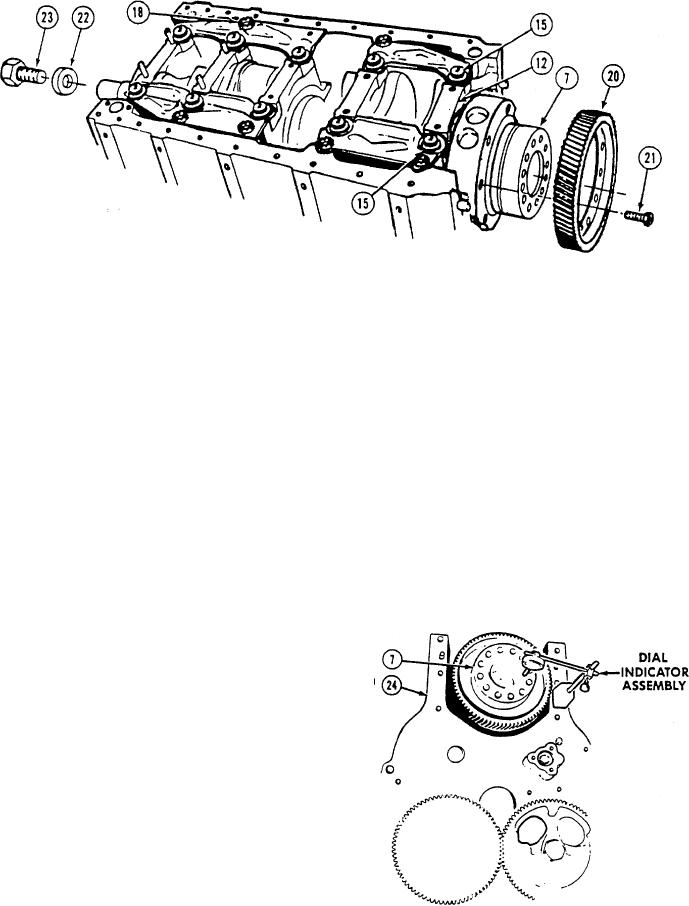

(33) Tighten two screws (15) on rear bearing cap (12) to 50 Ib-ft (68 Nm).

(34) Strike both ends of crankshaft (7) two or three blows with soft-face hammer.

(35) Strike rear bearing cap (12) with soft-face hammer.

(36) Tighten two screws (15) on rear bearing cap (12) to 110 Ib-ft (149 Nm).

(37) Strike rear bearing cap (12) with soft hammer.

(38) Torque two screws (15) on rear bearing cap (12) to 230 to 240 Ib-ft (312 to 325 Nm).

(39) Torque seven screws (18) to 70 to 75 Ib-ft (95 to 102 Nm).

(40) Install timing gear (20) and six screws (21).

(41) Install spacer (22) and screw (23) on end of crankshaft (7).

(42) Hold front end of crankshaft (7) while tightening six screws (21) to 35 to 39 Ib-ft (47 to 53 Nm).

(43) Remove screw (23) and spacer (22) from

crankshaft (7).

(44) Install dial indicator on engine block (24).

Push crankshaft (7) towards gauge with

pry bar while adjusting dial indicator to

zero.

(45) Read end play while removing pry bar and

forcing crankshaft in opposite direction.

Minimum end play is 0.004 in. (0.102 mm)

and maximum end play is 0.018 in. (0.457

mm). If end play is outside limits, replace

crankshaft (7).

6-159