TM 5-4210-233-14&P-2

6-29. MAIN BEARINGS AND CRANKSHAFT-Continued

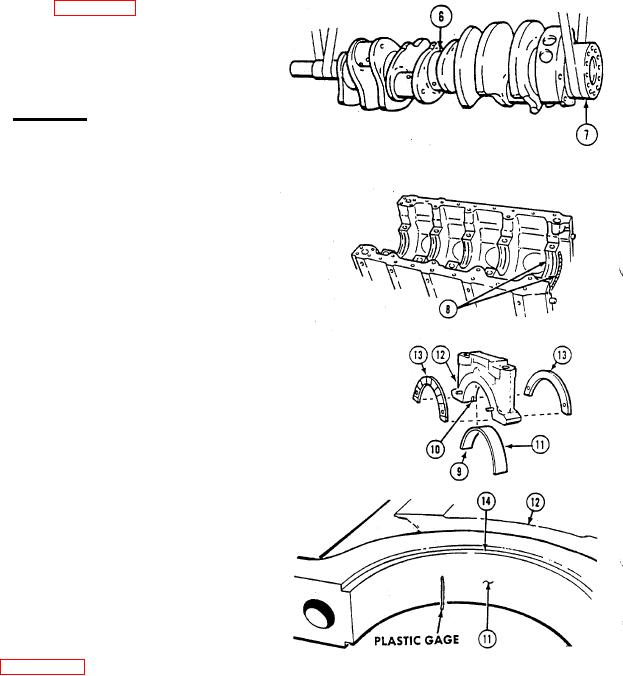

(4) Apply oil (item 10, Appendix E) to five

crankshaft main bearing journals (6).

(5) Attach suitable lifting device to crankshaft

(7).

WARNING

Serious injury could occur if heavy equipment if

moved/lifted without sufficient personnel to do the

job. Use proper physical lifting procedures or use a

suitable lifting device or dolly. Wear safety shoes,

gloves and other suitable protective clothing. Area

should be clear of other personnel. Serious injury

or death can result from failing objects.

(6) Operate lifting device while installing

crankshaft (7).

(7) Push crankshaft (7) to front and install

thrust washer (8). Push crankshaft (7) to

rear and install other thrust washer.

(8) Align tab (9) with slot (10) and install

bearing shell (11), making sure both ends

of bearing shell are flush with bearing cap

(12) mounting surfaces.

(9) Install four bearing shells (9) on other

bearing caps (12).

(10) Install two thrust washers (13) on rear

bearing cap (12) so that grooved sides of

thrust washers point away from bearing

cap.

NOTE

Wipe oil (item 10, Appendix E) from bearing shells

and crankshaft main bearing journals before doing

steps (11) to (13).

(11) Place strip of plastic gauge across width

of bearing shell (11) -in. (6 mm) from

center (14).

(12) Do step (11) for four other bearing caps

(12).

6-154