TM 5-4210-233-14&P-2

6-23. CAM FOLLOWER REPAIR

This task covers:

a.

Cleaning/inspection

c.

Assembly

b.

Disassembly

d.

Follow-on Maintenance

TOOLS REQUIRED

MATERIALS/PARTS REQUIRED

Tool Kit, General Mechanics, Automotive

Solvent, dry cleaning (Item 3, Appendix E)

(Appendix B, Section III, Item 1)

Oil, lubricating (Item 10, Appendix E)

Shop Equipment, Automotive

EQUIPMENT CONDITION

Maintenance and Repair

Cam Followers and Push Rods Removed

(Appendix B, Section III, Item 4)

(see para 6-22.)

Set, dial indicator (Appendix B, Section III, Item 32)

Gauge, feeler (Appendix B, Section III, Item 38)

a.

Cleaning/inspection.

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous.

Avoid repeated and prolonged breathing of vapors and

skin contact with the liquid. Do not use near open flame,

arcing equipment or other ignition sources. Always wear

eye protection and protective clothing. The flash point of

P-D-680 is 100 to 138 deg. F (38 to 59 deg. C).

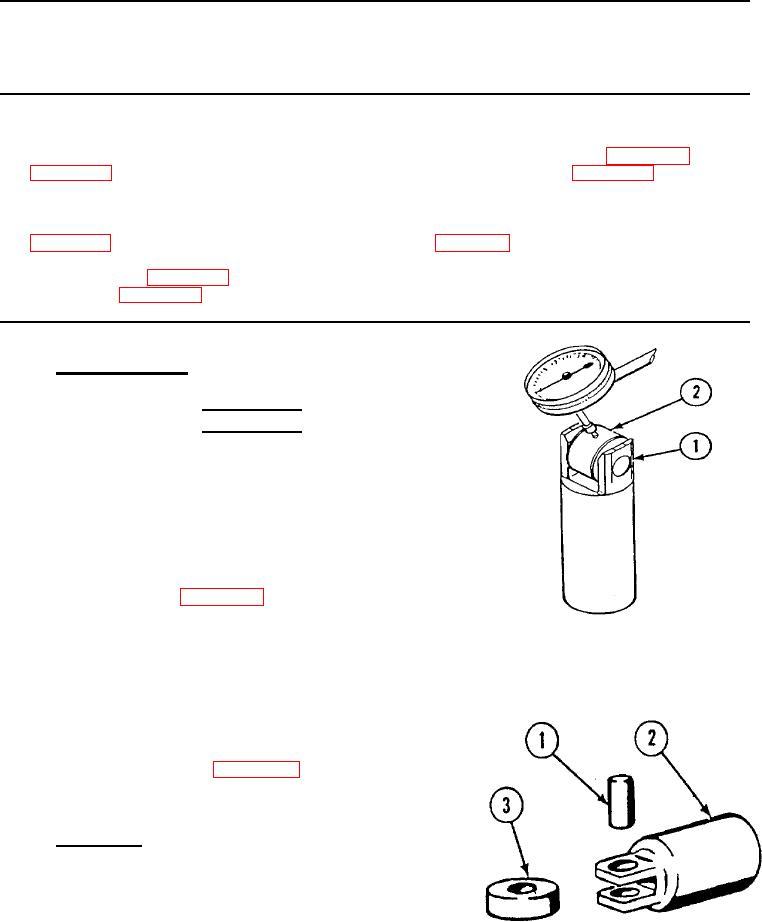

(1) Clean cam follower (1) with dry cleaning

solvent (Item 3, Appendix E).

(2) Inspect cam follower (1) for damage.

(3) Check side clearance between cam follower body (1) and roller (2) is not more than 0.023 in. (0.58

mm). If clearance is more than 0.023 in. (0.58 mm) go to step b.

(4) Put cam follower in vise. Check for more than

0.010 in. (0.25 mm) pin-to-bushing clearance

using dial indicator (Appendix B, Section !Ii,

Item 32). If clearance is more than 0.01 0 in.

(0.25 mm) go to step b.

b.

Disassembly.

NOTE

Pin and roller must be replaced together.

(1) Drive pin (1) out of cam follower body (2).

(2) Remove roller (3).

6-121