DRAFT

TM 5-4210-249-13&P-1

0060

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

HWT1159

TFFT02764

WARNING

ICON 15

Ensure PTO area is clear of personnel and obstructions before engaging PUMP

PTO switch. Failure to comply may result in injury or death to personnel and/or

damage to equipment.

NOTE

Ensure system air pressure is at least 85 psi (586 kPa) during this procedure. System air

pressure is required to activate valves.

Step 2.

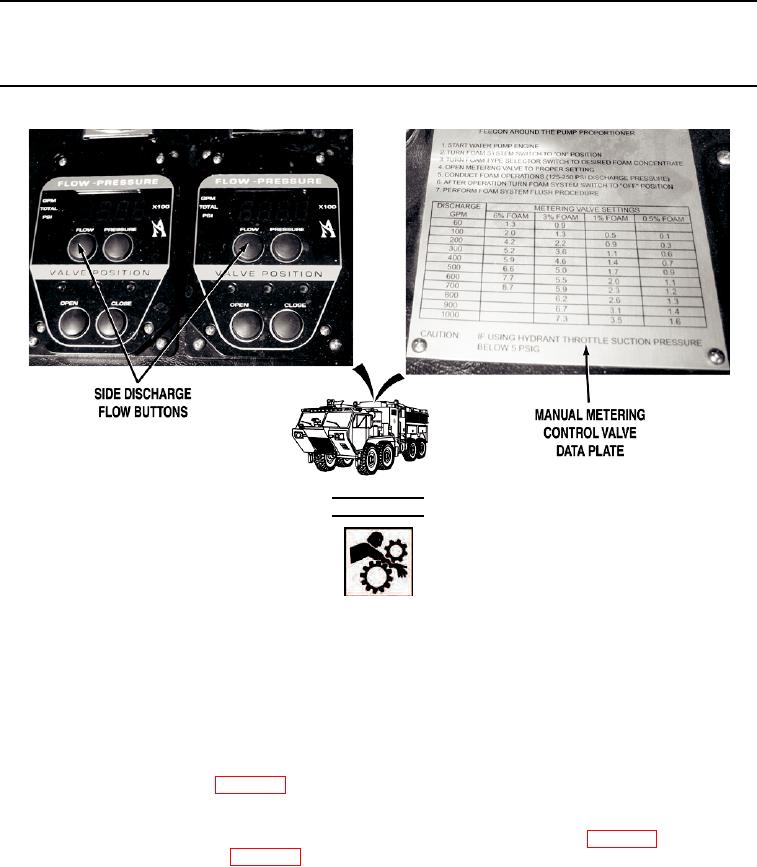

Start engine (TM 9-2320-347-10). Set up system to pump from onboard water

tank (WP 0026). When discharging from NO.1 DRIVER SIDE DISCHARGE or NO. 2

PASSENGER SIDE DISCHARGE, press FLOW button on valve control. Record GPM

rate, using settings from manual metering control valve data plate, set manual metering

valve to match discharge rate of flow. Operate bumper turret (WP 0035), ground

sweeps (WP 0039), or side discharge. Check if foam is delivered when system is

operated.

a.

If foam is delivered, problem has been corrected.

b.

If Foam A or Foam B is not delivered from either discharge, notify

Supervisor.

0060-3