DRAFT

TM 5-4210-249-13&P-1

0044

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TFFT00707P

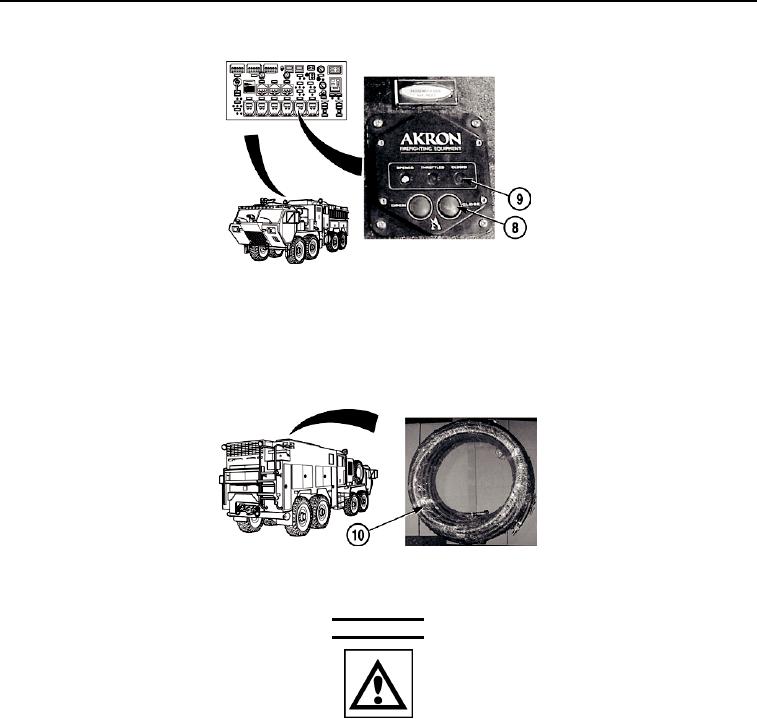

10. Make sure PASSENGER SIDE AUXILIARY INLET valve control (8) is in CLOSED position. Indicator light (9)

will illuminate.

11. Make sure all valves are closed.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TFFT00708P

12. Remove air hose (10) from stowage.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

WARNING

ICON 72

Be careful when using high air pressure. Make sure connections and seals are tight

before applying pressure. High air pressure can blow out parts, hoses, or debris

with force. Explosive force can cause damage to equipment or injury to personnel.

Wear single hearing protection (earplugs or equivalent) while working around

compressed air. Failure to comply may result in damage to your hearing. Seek

medical aid should you suspect a hearing problem.

Air pressure should not exceed 50 psi (345 kPa) during blow-out procedure. Failure

to comply may result in damage to equipment. Failure to comply may result in

injury to personnel.

13. Connect air hose (10) to blow-out adapter (7) on PASSENGER SIDE AUXILIARY INLET (6) and regulated air

supply.

14. If using vehicle for air supply, start vehicle engine (TM 9-2320-347-10).

0044-3