TM 5-4210-233-14&P-2

6-15. INJECTOR TUBES - Continued

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138

deg.F (38 to 59 deg. C).

(11) Wash injector tube (1) with dry cleaning solvent

(item 3, Appendix E).

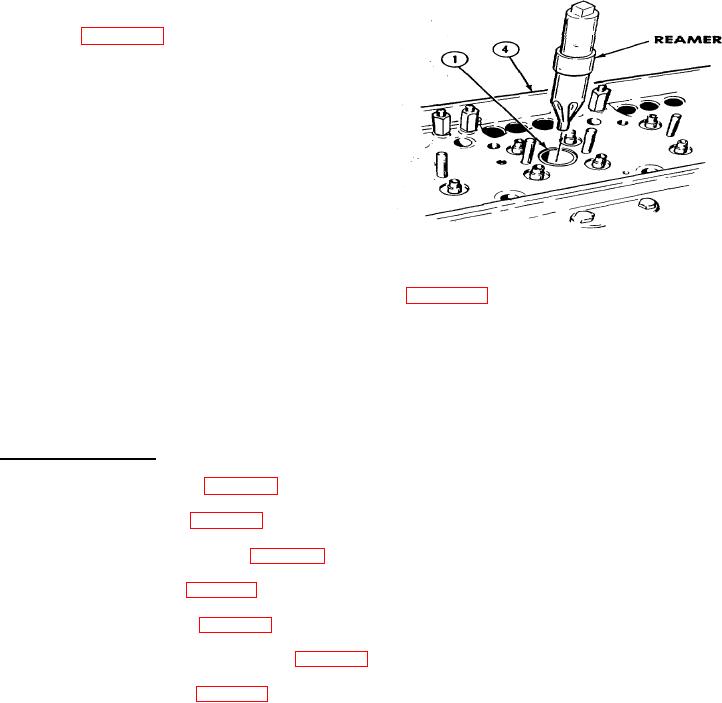

(12) Lubricate reamer blades while reaming injector

tubes.

CAUTION

Counterclockwise reaming will damage reamer

blades and injector tube.

(13) Ream injectortube (1) clockwise.

(14) Clean filings from injectortube (l).

(15) Repeat steps (11) through (14) until protrusion gauge is flush 0.014 in. (0.36 mm).

(I6) Clean injector tube (1) with dry cleaning solvent (Item 3, Appendix E).

WARNING

Compressed air used for cleaning purposes will not exceed 30

psi (207 kPa). Use only with effective chip guarding and

personal protective equipment (goggles/shield, gloves, etc.)

(17) Dry with compressed air.

c.

Follow-on Maintenance.

(1) Install exhaust valves (see para 6-20).

(2) Install fuel injectors (see para 6-43).

(3) Install exhaust valve bridges (see para 6-24).

(4) Install rocker arms (see para 6-21).

(5) Install brake retarder (see para 6-34).

(6) Install cam followers and push rods (see para 6-22).

(7) Install cylinder head (see para 6-13).

6-100