DRAFT

TM 5-4210-249-13&P-4

0599

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TFFT01626

3.

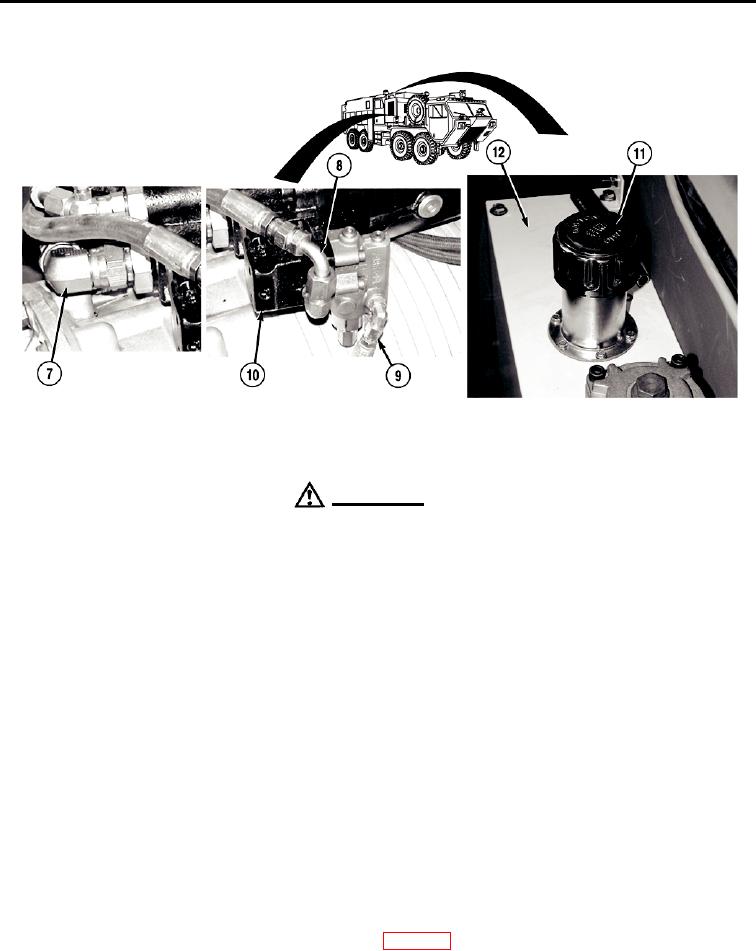

Loosen hydraulic hoses (7), (8), and (9) and check for steady flow of hydraulic oil at hydraulic pump (10).

CAUTION

Do not over pressurize hydraulic reservoir. Failure to comply may cause damage to

equipment.

NOTE

Perform Steps (4) through (7) only if necessary to pressurize hydraulic system for

hydraulic oil flow.

4.

Use a clean cloth and air hose to pressurize hydraulic reservoir.

5.

Ensure air is slowly added to reservoir only. Do not mix air with oil.

6.

With the aid of an assistant, remove breather cap (11) from hydraulic reservoir (12) and pressurize hydraulic

reservoir (12), while checking for oil flow at hydraulic pump (10).

7.

Install breather cap (11) on hydraulic reservoir (12).

8.

Tighten hydraulic hoses (7), (8), and (9) and wipe dry.

9.

Start engine (TM 9-2320-347-10) and warm up until normal idle speed.

10. Loosen hydraulic hose (9) and allow steady flow of hydraulic oil until no bubbles are visible.

11. Tighten hydraulic hose (9) and check for oil leaks.

12. Increase engine speed to operating RPM (WP 0021) and hold without load 10-15 minutes allowing hydraulic

system to remove air and fill hydraulic reservoir (12) (WP 0588).

13. Apply load on hydraulic system (WP 0021) and check generator output.

0599-2