TM 5-4210-233-14&P-2

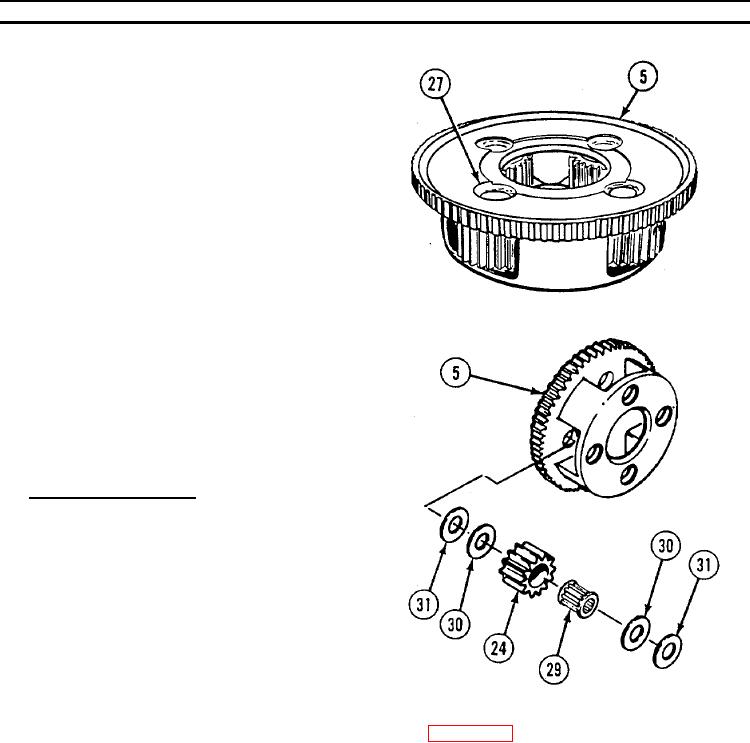

6-55. GEAR UNIT AND MAIN SHAFT ASSEMBLY - Continued

(21) Drill away staked front ends of center carrier

assembly (5) pinion pins (27) using a 15/16-

in. (23.8 mm) bit.

(22) Drill away staked ends of rear carrier

assembly (20) pinion pins (28) using a 1-

3/16-in. (30.2 mm) bit.

NOTE

Front, center, and rear carrier

assemblies are disassembled the same

way. Disassembly of center carrier is

shown.

(23) Position center carrier assembly (5) with

drilled ends of pinion pins (27) upward in

press.

(24) Press pinion pins (27) from center carrier

assembly (5).

(25) Remove pinions (24), roller bearings (29),

steel thrust washers (30), and bronze thrust

washers (31) from center carrier assembly.

c.

Cleaning and Inspection.

WARNING

Dry cleaning solvent P-D-680 is

potentially dangerous. Avoid repeated

and prolonged breathing of vapors and

skin contact with the liquid. Do not use

near open flame, arcing equipment or

other ignition sources. Always wear eye

protection and protective clothing. The

flash point of P-D-680 is 100 to 138

deg. F (38 to 59 deg. C).

(1)

Clean all metal parts with dry cleaning solvent (Item 3, Appendix E).

NOTE

All planetary gears in a carrier assembly are replaced as a set.

(2)

Inspect parts for damage. Replace damaged parts.

(3)

Measure thickness of thrust washers. Thickness must be no less than 0.091 in. (2.31 mm).

6-305