TM 5-4210-233-14&P-2

6-8. CYLINDER BLOCK- Continued

(25)

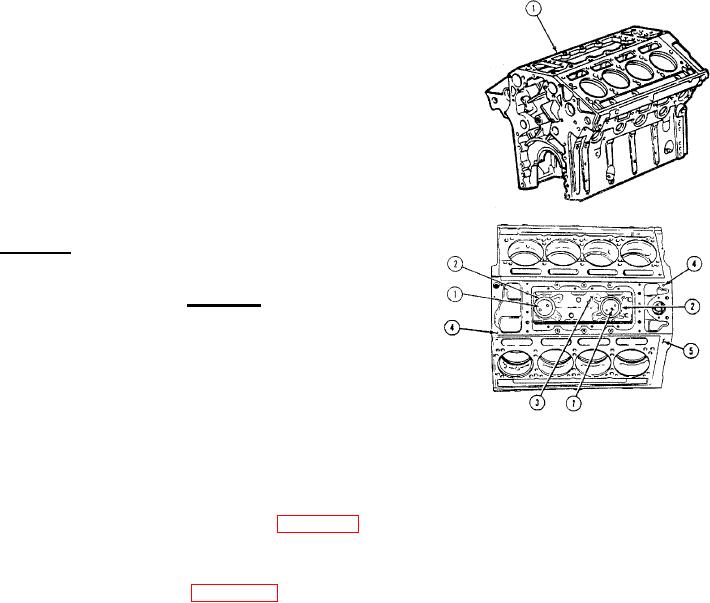

Inspect dowel holes in engine block (1) for oversize

holes or damage. Replace engine block if damaged

or oversize.

(26)

Inspect threaded holes for stripped or crossed

threads. Use a tap to clean up threads.

(27)

Inspect machined surfaces for flatness, burrs, and

scratches. If surfaces cannot be cleaned up by

lapping, replace engine block (1).

c. Assembly.

WARNING

Adhesives, solvents, and sealing

compounds can burn easily, can

give off harmful vapors, and are

harmful to skin and clothing. To

avoid injury or death, keep away

from open fire and use in well-

ventilated area. If adhesive, solvent,

or sealing (e compound gets on skin or clothing, wash immediately with soap and

water.

NOTE

Coat threads of ail serviceable plugs, fittings, and draincocks with pipe thread

sealing compound (Item 2, Appendix E) and transfer to new engine block (if

applicable).

(1)

Use core plug installer (Appendix B, Section Iii, Item 16) to install two core plugs (1) and new

gaskets (2) inside air box (3). Tighten plugs to 230 to 270 lb-ft (312 to 366 Nm).

(2)

Install two 1/4-in. oil galley plugs (4) in top of engine block (5).

(3)

Tighten plugs (4) to 14 to 16 lb-ft (1 9 to 22 Nm).

6-54