TM 5-4210-233-14&P-2

6-8. CYLINDER BLOCK - Continued

NOTE

Main bearing caps must be installed

in proper positions in engine block.

Bearing caps are numbered 1 thru 5

to correspond with their respective

positions in the cylinder block.

Number 1 cap is front cap. Make

sure caps are firmly seated in engine

block and main bearing shells are

removed.

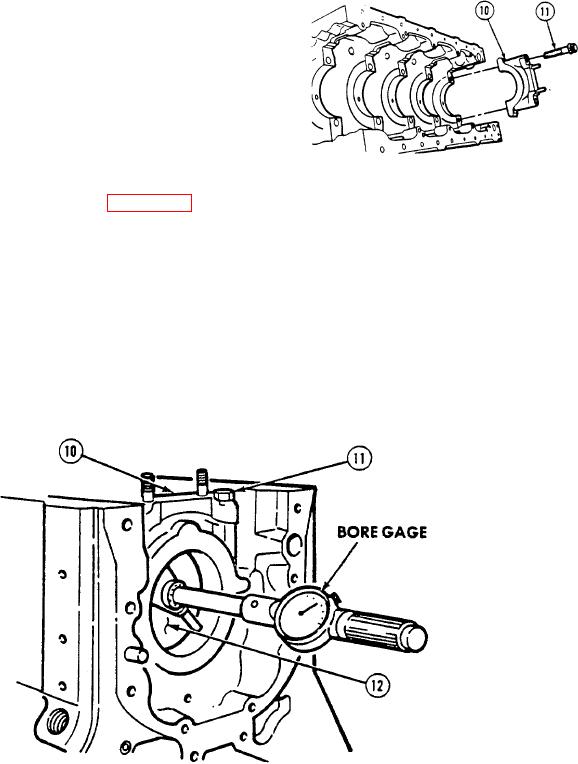

(17)

Install five main bearing caps (10) and ten screws

(11). Lubricate threads and head contact surfaces with a small quantity of International

Compounds No. 2 (Item 37, Appendix E).

(18)

Tighten screws (11) up snug.

(19)

Strike caps (1 0) with soft-face hammer to seat them.

(20)

Tighten screws (11) to 50 lb-ft (68 Nm).

(21)

Tighten screws (11) to 110 lb-ft (149 Nm).

(22)

Tighten screws (11) to 230 to 240 lb-ft (312 to 325 N-m).

(23)

Use bore gauge to measure each main bearing bore (12) diameter. If main bearing bore diameter

is less than 4.812-in. (122.22 mm) or is greater than 4.813-in. (122.25 mm), replace engine block

(1).

(24)

Remove five main bearing caps (10) and screws (11).

6-53