TM 5-4210-233-14&P-2

6-8. CYLINDER BLOCK- Continued

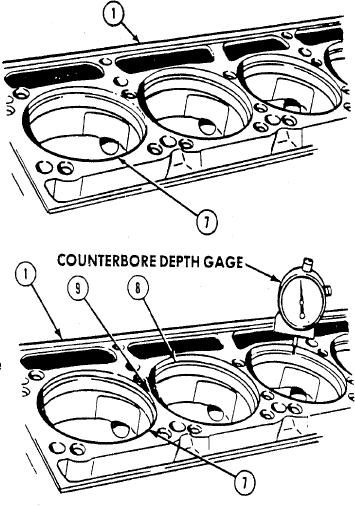

(11) Use straight edge and feeler gauge to

measure flatness of engine block (1)

crosswise, between all cylinders (7).

(12) If block (1) varies more than 0.003-in.

(0.076 mm), replace engine block (1).

(13) Using a straight edge and feeler

gauge, measure flatness of engine

block contact surface (1) lengthwise.

If block (1) varies more than 0.007-in.

(0.178 mm), replace engine block (1).

NOTE

Cylinders may be counterbored

to either of two depths.

(14) Using counterbore depth gauge,

measure depth of counterbore (8). If

depth is not between 0.4755-in.

(12.08 mm) and 0.477-in. (12.12 mm)

or between 0.4905-in. (12.46 mm)

and 0.4920-in.

(12.50 mm) and

cannot be brought into limits by

installing cylinder liner insert, replace

engine block.

(15) If counterbore (8) varies more than

0.0015-in. (0.04 mm) around edge of

cylinder, replace engine block (1).

NOTE

If two adjacent cylinders are in different counterbore depth ranges measured in

step (14) above, step (16) does not apply.

(16) If difference between any two adjacent cylinder counterbores (8) measured at their closest point (9)

is more than 0.0015-in. (0.04 mm), replace engine block (1).

6-52