DRAFT

TM 5-4210-249-13&P-1

0095

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

TFFT04032

CAUTION

Do not mix different types or brands of foam agent in foam tanks or piping. Mixing

of different foam agents (either type or manufacturer) may cause deterioration of

foam agent, improper proportioning and poor performance in a fire situation.

Mixing of Class A and Class B foam agents may result in a chemical reaction which

can create globules, which can clog orifices and cause system failure.

Step 1.

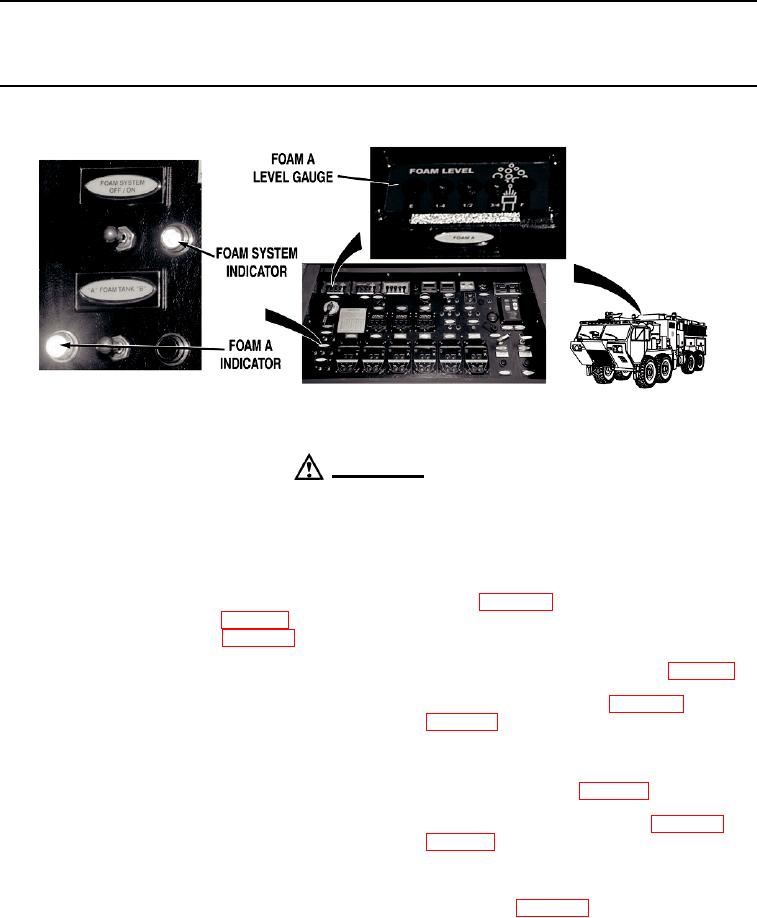

Turn battery disconnect switch to ON position (WP 0007). Open pump operator's

panel (WP 0019). Check level indicated at pump operator's panel FOAM A LEVEL

gauge (WP 0004).

If FOAM A LEVEL gauge indicated E (empty), fill foam A tank (WP 0031).

Step 2.

Put pump operator's panel FOAM SYSTEM switch to ON position (WP 0004). Check if

FOAM SYSTEM indicator illuminates (WP 0004).

If FOAM SYSTEM indicator does not illuminate, troubleshoot Foam Not

Delivered From All Systems (Bumper Turret, Ground Sweeps, and Manual

Metering Controls) or System Does Not Shut Off (WP 0094).

Step 3.

Put and hold pump operator's panel FOAM TANK switch to "A" position (WP 0004).

Check if foam A indicator illuminates (WP 0004).

If foam A indicator does not illuminate, go to Step 24.

Step 4.

Release pump operator's panel FOAM TANK switch (WP 0004). Check if foam A

indicator remains illuminated.

If foam A indicator remains illuminated, go to Step 13.

0095-2