DRAFT

TM 5-4210-249-13&P-1

0040

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TFFT00287P

1.

Using pressure governor, decrease engine RPM to reduce water pressure (WP 0024).

2.

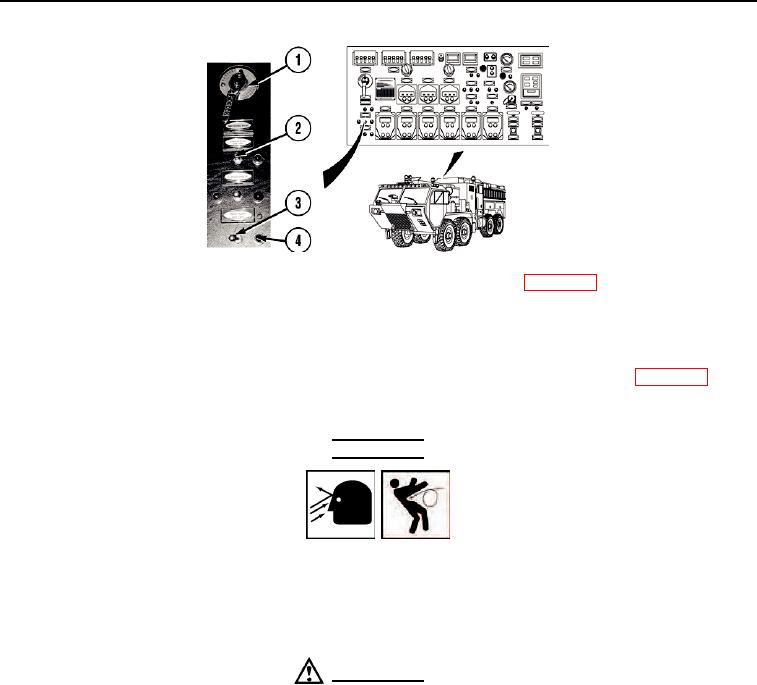

Make sure foam METERING VALVE (1) is in CLOSED position.

3.

Make sure FOAM SYSTEM switch (2) is in OFF position.

4.

Using pressure governor, adjust main water pump discharge pressure to 125 psi (862 kPa) (WP 0024).

5.

Turn FOAM FLUSH switch (3) to ON position. Indicator light (4) will illuminate.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

WARNING

ICON 5, 66

Open and close all valves slowly during any procedure. Sudden changes in

pressure may cause equipment to react faster than personnel can be alerted.

Ensure surrounding personnel are aware of changes being made to settings on

equipment. Failure to comply may result in injury or death to personnel and

damage to equipment.

CAUTION

Do not open any foam agent supply tanks while performing flush procedures.

Do not allow foam system pressure to exceed 250 psi (1,724 kPa). Failure to comply

may result in damage to equipment.

6.

Put foam METERING VALVE (1) in fully opened position.

NOTE

Perform Steps (7) through (13) if discharges were used.

While flushing, open and close METERING VALVE two times; continue flushing until water

runs clear.

7.

Open discharge valves and flush out all discharges that were used, removing foam until water runs clear.

8.

While flushing, open and close foam METERING VALVE (1) twice or until water runs clear from discharge.

9.

Flush portable equipment such as hoses, nozzles, monitors, etc.

0040-2