DRAFT

TM 5-4210-249-13&P-1

0026

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

TFFT04838

6.

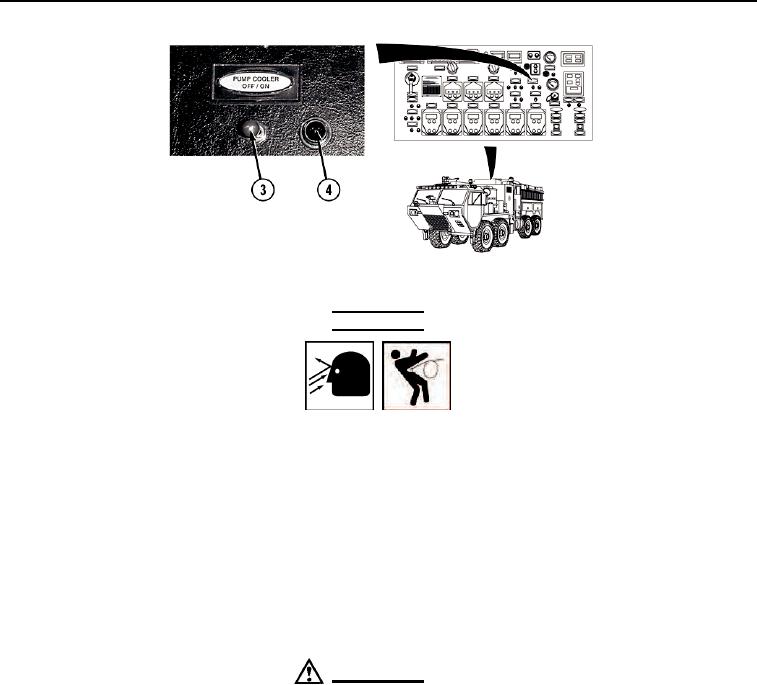

Put PUMP COOLER switch (3) to ON position indicator (4) will illuminate.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

WARNING

ICON 5, 66

Discharge caps should not be removed if water system is under pressure.

Discharge caps can act as projectiles if released under pressure causing injury or

death to personnel.

Open and close all valves slowly during any procedure. Sudden changes in

pressure may cause equipment to react faster than personnel can be alerted.

Ensure surrounding personnel are aware of changes being made to settings on

equipment. Failure to comply may result in injury or death to personnel and

damage to equipment.

If any discharge hose is used, make sure hose is removed from hose bed, nozzle is

securely attached, and nozzle is turned off before opening any discharge valves.

Failure to comply may result in injury to personnel.

CAUTION

Cavitation can occur when pumping and air enters water. If engine speed increases

without an increase in pressure, pump may be cavitating. Even though pump may

be primed, air leaks can cause rough operation and an increase in engine speed

without an increase in pressure or flow. If an air leak is suspected, discontinue

pumping and isolate problem. Cavitation can also occur with large nozzle tips.

Solve this problem by reducing flow. Failure to comply may result in damage to

water pump.

0026-2