TM 54210-233-14&P-2

6-20. EXHAUST VALVES - Continued

b. Cleaning/Inspection.

WARNING

Dry cleaning solvent P-D-680 is potentially dangerous. Avoid

repeated and prolonged breathing of vapors and skin contact

with the liquid. Do not use near open flame, arcing equipment or

other ignition sources. Always wear eye protection and

protective clothing. The flash point of P-D-680 is 100 to 138 deg.

F (38 to 59 deg. C).

(1) Clean all metal parts with dry cleaning solvent (Item 3, Appendix E).

WARNING

Compressed air used for cleaning purposes will not exceed 30

psi (207 kPa). Use only with effective chip guarding and

personal protective equipment (goggles/shield, gloves, etc.)

(2) Dry all parts with compressed air.

(3) Inspect spring for pitting or fractures.

(4) Check tension of each spring using valve spring compressor. Replace spring when a load of less

than 25 lbs (11 kg) will compress it to 1.80 in. (45.72 mm) installed length.

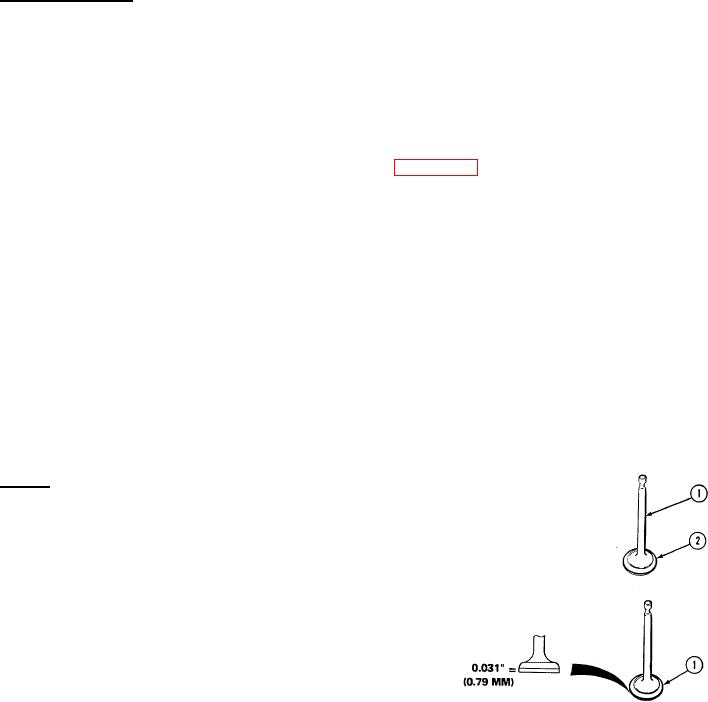

(5) Inspect valve stem (1) and valve face (2) for cracks, pitting, and warpage. Replace if damaged.

(6) Inspect outer diameter of valve face (2) for scoring or galling. Grind or replace as necessary.

c.

Repair.

NOTE

Valve seat must be ground before valve is

installed.

(1) Grind exhaust valve seat (1) using 300 grinding

stone.

(2) Edge of valve seat (1) must not be less than

0.031 -in. (0.79 mm) thick after grinding.

6-110