TM 5-4210-233-14&P-2

6-8. CYLINDER BLOCK- Continued

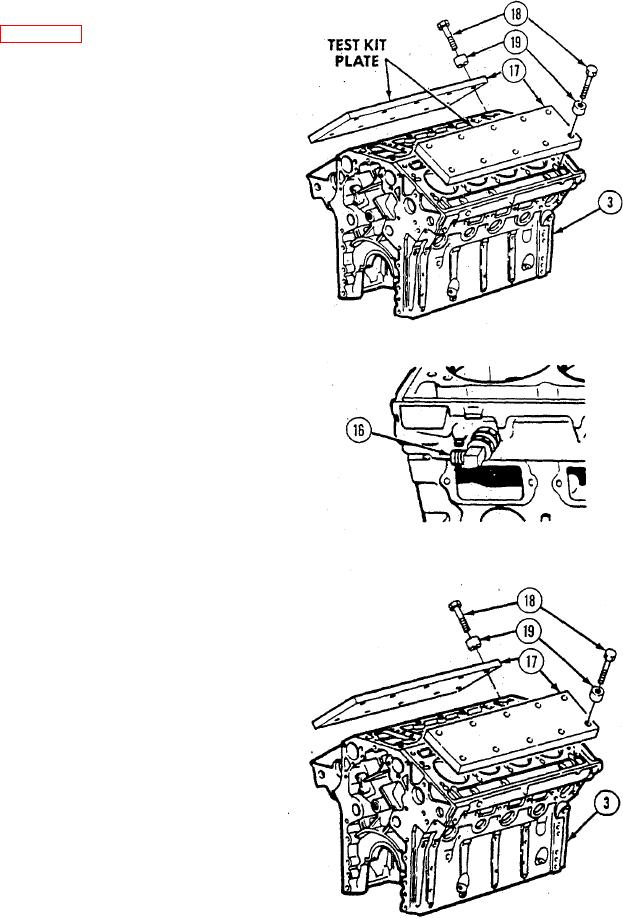

(12)

Install two plates (17) from engine block test

kit (Appendix B, Section 111, Item 20) on

right and left cylinder banks of engine block

(3) with 20 head screws (18) and spacers

(19).

(13)

Tighten screws (18) to 50 lb-ft (68 Nm)

then to 1 10Ib-ft (149 Nm).

WARNING

Be careful when using high

air pressure. Make sure

connections and seals are

tight

before

applying

pressure. High air pressure

can blow out parts, hoses,

or

debris with force.

Explosive

force

can

damage equipment and

cause injury.

(14)

Apply 40 psi (276 kPa) pressure to engine

block (3). Maintain this pressure for at least

two hours.

(15)

After test period, inspect engine block (3)

for leaking antifreeze. If leaks are found in

engine block, engine block must be

replaced.

(16)

Relieve 40 psi (276 kPa) pressure from

engine block (3).

(17)

Disconnect air line from fitting (16).

(18)

Remove 20 screws (18), spacers (19), and

two plates (17) from engine block (3).

6-62