|

| |

TM 9-254

4-17.

Printed Circuit Boards - Continued

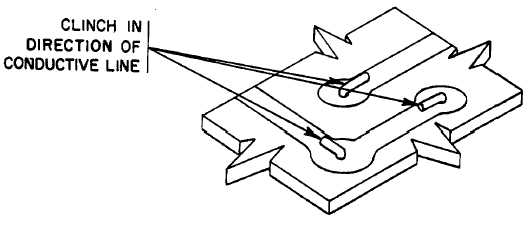

Figure 4-39. Direction of Pigtail Cinch

(6)

Component leads that cannot be bent or clinched flush with the circuit should be properly cleaned and

cut to a length that will permit the lead to extend one thirty-second of an inch above the solder pad.

Components mounted in this manner shall be secured rigid to the board with a suitable mounting clamp

or approved resin.

(7)

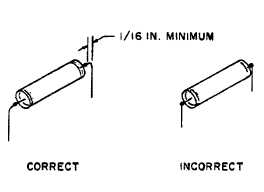

With tantalytic capacitors and other components which have welded leads, the bend should be

measured from the weld rather than from the component body as shown in figure 4-40.

Figure 4-40. Welded Lead with Proper Bend

e.

Handling. Whenever practicable, the manual handling of printed circuit pads, terminals, and component

leads should be avoided. When manual handling is necessary, wear white gloves to prevent body acids from

contaminating the item.

f.

Component Mounting (fig. 4-41). Components should be mounted flush with the circuit board unless potted

or supported by a suitable retaining clamp.

g.

Cleaning. When soldering printed circuits, clean circuit pad with a swab or brush and alcohol. A soft eraser

may be used if the alcohol method fails to clean the area properly. After cleaning with an eraser, lightly brush to remove

eraser particles.

4-43

|