|

| |

TM 9-254

4-17.

Printed Circuit Boards - Continued

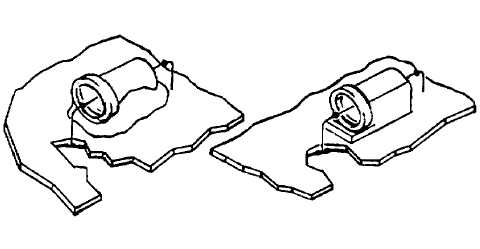

Figure 4-41. Flush Mounting - Examples

h.

Soldering. To prevent damage from excessive heat the soldering iron should never be left in contact with the

printed-wiring conductor for longer than 5 seconds on paper baseboards, or 8 seconds on fiberglass epoxy baseboards.

Excessive heat will cause delamination. If soldering operations exceed the time limits, allow a 30 second cooling period

before continuing the soldering operation.

i.

Component Weight. Component parts that weigh one-half of an ounce or more should be secured by a

suitable mounting bracket or potted with an approved epoxy resin.

j.

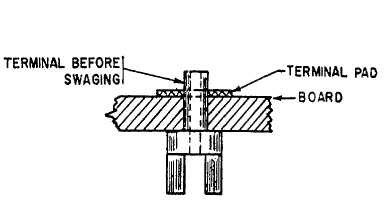

Mounting and Soldering Terminals. When mounting and soldering terminals to printed circuit wiring boards,

the procedures listed below should be followed:

(1)

Drill the pad hole to a diameter that will permit the terminal shank to be pressed through the board by

hand. A press fit is not necessary, but the terminal should fit snugly enough to prevent it from falling out.

(2)

Clean the terminal pad with a swab or brush and alcohol. If this method fails to clean the area properly, a

soft eraser may be used.

(3)

Press the terminal shank through the board and aline the terminal as shown in figure 4-42.

Figure 4-42. Terminal Before Swaging

4-44

|