|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

STEERING GEAR

to an internal combustion engine. The housing

should be replaced if the steering gear is tested

thoroughly and it can definitely be determined that

cylinder bore scoring is responsible for excessive

internal leakage.

39.

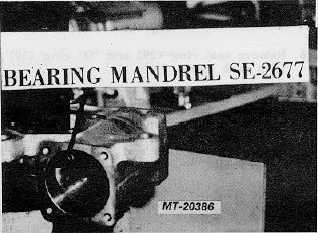

If bearing (21) and retaining ring (22) require

replacement they must be pressed out of housing

(20). Care must be taken to maintain a good square

relationship between housing and press base, to

avoid damaging bearing bore. If bearing is "cocked"

while being pressed out, it may burnish housing bore,

causing it to be oversize and require housing

replacement. Use bearing mandrel SE-2677 to press

bearing out (Fig. 20).

Fig. 20

REASSEMBLY

IMPORTANT

All gaskets, seals and seal rings should be replaced each time

steering gear assembly is fully disassembled. If

steering gear is partially disassembled all gaskets,

seals and seal rings in area effected should be

replaced.

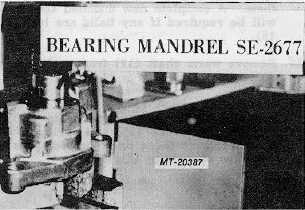

1.

Press new bearing (21) into housing (20) using

bearing assembly mandrel SE-2677. Care must be

taken during this procedure to make sure that

housing is square with press base and that bearing is

not in a "cocked" position. Apply a generous amount

of clean wheel bearing grease to bearing race to

retain bearing rolls; assemble forty four bearing rolls,

grease must retain rolls (Fig. 21).

2.

Assemble "O" ring (30) and seal ring (29) onto rack

piston (31).

Fig. 21

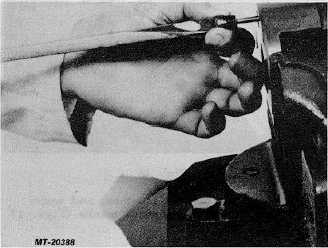

3.

Assemble spring (36), rod (35), poppets (34), poppet

seals (33) and retaining ring (32) into rack piston

(31). Torque poppet seats to 27-34 Nm (20-25

ft.lbs.)(Fig. 22).

Fig. 22

4.

Assemble "O" ring (18) and seal ring (19) onto worm

shaft (17), use installation and compression tools

SE-2673 and SE-2674 to assemble these ports (Fig.

23).

5.

Grease seal ring (19) area and assemble worm shaft

(17) into rack piston (31)(Fig. 24).

6.

Assemble ball return guides (43) into rack piston

(31).

7.

Assemble balls (42) into ball return guides (43) and

rack piston (31); drop balls thru the hole provided in

the ball return guides. Rotate the worm shaft (17) as

balls are being assembled to pull balls down into

groove, assemble twenty-seven balls. Make sure ball

return guides stay down in place in rack piston while

assembling balls (Fig. 25).

CTS-2717 Page 8

PRINTED IN UNITED STATES OF AMERICA

|