|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

STEERING GEAR

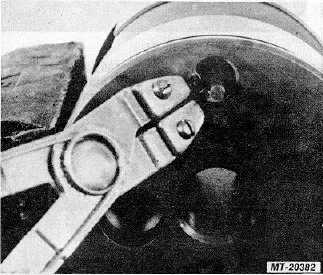

special care must be exercised to not lose them. A

complete new matched set of balls will be required if

any balls are lost (Fig. 15),.

33.

Remove worm shaft (17) from rack piston (31).

34.

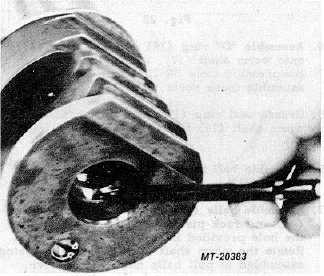

Clamp rack piston (31) in a vise to remove retaining

rings (32), poppet seats (33), poppets (34), rods (35)

and spring (36). Do not remove these parts unless

there is evidence of damage (Fig. 16).

Fig. 16

35.

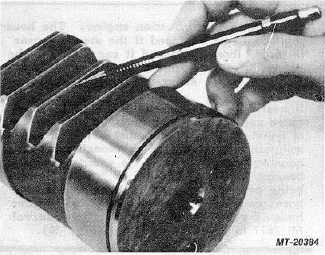

Inspect rack piston (31) teeth and worm groove for

excessive wear marks (Figs. 17 and 18).

Fig. 17

Fig. 18

36.

Remove seal ring (29) and "O" ring (30) from rack

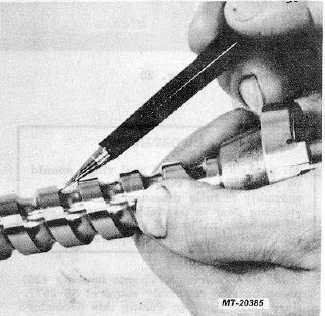

piston (31). 37. Inspect worm shaft (17) helical

groove for brinelling (Fig. 19). If this condition is

visible the rack piston (31), valve sleeve (15) and

worm shaft must be replaced. Remove seal ring (19)

and "O" ring (18) from worm shaft.

Fig. 19

38.

Inspect housing (20) for abnormal wear, scoring or

damage. The housing should not be replaced simply

because the cylinder bore may exhibit considerable

scoring, this scoring should not be rated in any

manner relative to the type scoring which is critical

CTS-2717 Page 7

PRINTED IN UNITED STATES OF AMERICA

|