|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

INSTALLATION

Lubricate the splines thoroughly (refer to page 9) and

assemble on the shaft. BE SURE that the arrows or marks on

the shaft and slip joint are in line, since the sleeve yoke lugs

must be in the same plane as the stud ball yoke lugs to

prevent excessive vibration (Fig. 37).

The cork washer should be replaced is necessary before

assembling with the dust cap and steel washer on the sleeve

yoke.

INSTALLING PROPELLER SHAFT

1.

Propeller Shaft Assembly Place in a pair of centers

and check the shaft for run-out if not previously done

during assembly. The run-out on the tube should not

be more than .38 mm (.015") indicator reading, and

on the neck of the slip stub shaft the run-out should

not be more than .12 mm (.005") indicator reading.

Mark the high and low points on the shaft with chalk

and straighten if necessary. Install with the slip joint

nearest the source of power. Tighten the flange bolts

evenly after the nuts and NEW lockwashers are in

place.

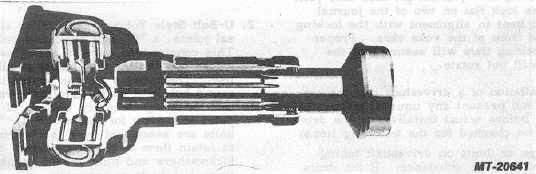

Fig. 38

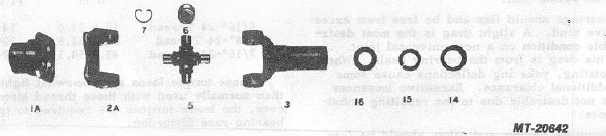

Fig. 39

TWO-JOINT PROPELLER SHAFT

It is of primary importance that universal joints of

sufficient capacity be used. When assembling the slip joint on

the shaft, care must be taken to place the sleeve yoke lugs

(12) in the same plane as the shaft yoke lugs (13). Arrows will

be found stamped on the sleeve and shaft for this purpose.

Install transmission so that the transmission main

shaft and axle pinion shaft are parallel or nearly so, in order to

keep the angles (X) on both joints as nearly equal as possible.

See Fig. 40. If this method results in angles (X) of more than

12 deg., use the method shown in Fig. 41, where the axle

pinion shaft is tilted upward to enable the centerlines to

intersect at a point midway between the joint centers, thus

giving equal angles (Y).

CTS-2730 Page 20

PRINTED IN UNITED STATES OF AMERICA

|