|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

INSTALLATION

Fig. 36

JOURNAL CAPS WITH LOCK FLATS (Fig. 36)-

When installing new journal kit caps into yoke ear holes, the

lock flat on two of the journal caps must be kept in alignment

with the locking flats near the front of the yoke ears. Proper

location of locking flats will assure that the journal cap will not

rotate.

The installation of a driveshaft into the vehicle does

not present any unusual mechanical difficulties. Before actual

installation, the driveshaft should be checked for the following

items:

1.

No damage or dents on driveshaft tubing which could

cause unbalance. If the dents are severe enough

they can weaken the tube and a failure might occur

under torque load.

2.

Splines should slide freely with slight drag from

spline seal.

3.

Bearings should flex and be free from excessive bind.

A slight drag is the most desirable condition on a

new universal joint. This drag is from the bearing

seals. When rotating, yoke lug deflections cause

some additional clearance. Excessive looseness is

not desirable due to the resulting unbalance.

4.

Mounting flanges and pilots should be free from

burrs, paint and foreign substances which would not

allow proper seating at assembly.

The driveshaft is mounted using flange bolts, bearing

capscrews, or "U" bolts depending upon the size and

construction. These bolts must carry high torque loads and

should be of quality material and properly torqued. The

following reviews requirements on these bolts:

1.

Flange Bolts: Flange bolts should be alloy steel

equivalent to SAE Grade 8, high strength bolts.

These bolts used with spring lockwashers and nuts

provide the capacity required. The nuts should be

torqued to the following specifications:

N.m

Ft. Lbs.

5/16"-24 Thread

29.8-32.5

22-24

3/8"-24 Thread

54.2-59.6

40-44

7/16"-20 Thread

85.4-94.9

63-70

1/2"-20 Thread

132.9-146.4

98-108

IMPORTANT

In cap and bolt construction joints (Fig. 7), be

sure to torque the capscrews to 135.6 N.m

(100 ft.lbs.). These joints are usually in the

inter-axle assemblies.

2.

U-Bolt Style. Yokes: On smaller size universal joints,

a "U" bolt style end yoke is used. This construction

permits easier assembly where the smaller size

bearings allow its use. The bearing race is seated in

a half round hole and under locating ears. Be sure

that mounting faces are cleaned of rust, paint and

other foreign material. The "U" bolts are assembled

over the bearing races to retain them in the end

yokes. Spring lockwashers and nuts should be used

with these "U" bolts at assembly. The following

torque loads are suggested for use with these parts:

N.m

Ft. Lbs.

5/16"-24 Thread

18.9-23.0

14-17

3/8"-24 Thread

27.1-32.5

20-24

7/16"-20 Thread

43.3-50.1

32-37

These torque loads are somewhat lighter than

normally used with these thread sizes, however, the lower

torques are required to prevent bearing race distortion.

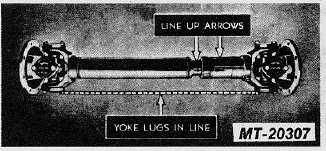

ASSEMBLING SLIP JOINT ON SHAFT

Fig. 37

CTS-2730 Page 19

PRINTED IN UNITED STATES OF AMERICA

|