|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

PROPELLER SHAFT

REBUILDING DRIVESHAFTS

BALANCING

The rebuilding of a driveshaft assembly usually

consists of replacing worn journal cross and bearings with a

new kit. These kits replace the part of a driveshaft most

subject to wear in operation. The slight off-center condition

present in the journal cross assemblies makes it desirable to

balance the assembly after installing new journal and bearing

kits.

Generally, unbalance resulting after installation of a

journal and bearing kit is equivalent to the unbalance existing

after straightening the shaft. If balancing cannot be done, it is

advisable to check assembly for smooth operation in vehicle

before it is put into operation.

It is sometimes necessary to revise driveshaft

lengths when rebuilding a vehicle. This job requires proper

facilities to produce a quality assembly. It is necessary to

properly assemble fittings into the tube and straighten, before

welding, to be sure parts are centralized. This can be done by

mounting shaft assembly on

center and straightening at fittings until ends of tube run

concentric within about .12 mm (.005") TIR. The welding of

the tube in the fittings must provide for adequate strength and

prevent distortion which could cause excessive run-out. It is

often desirable to tack weld and recheck for run-out before

proceeding with final weld. After welding, the entire driveshaft

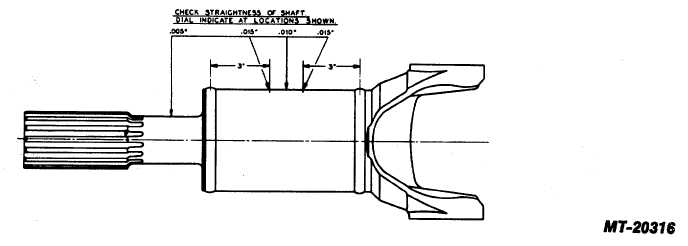

should be straightened to the following limits: (See Fig. 35)

.12 mm (.005") TIR

On shaft neck

.38 mm (.015") TIR

On ends of tubing 76.2

mm (3") from welds

.25 mm (.010") TIR

In center of tube

These run-outs should be taken with entire driveshaft

assembly mounted on master attaching flanges or yokes,

selected for dynamic balance to eliminate as much unbalance

as possible. During balancing, the driveshaft again should be

mounted on these selected flanges or yokes.

Fig. 35

CTS-2730 Page 18

PRINTED IN UNITED STATES OF AMERICA

|