|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

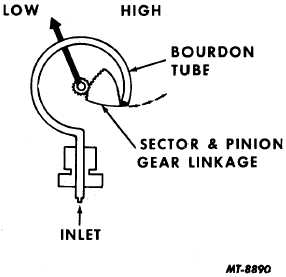

Fig. 23 Air Pressure Gauge Details

Remove

1.

Detach instrument cluster and cluster bezel.

2.

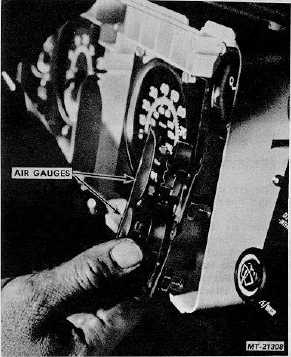

Unscrew air lines from fittings on rear of the two air

gauge inlets on back of instrument cluster.

3.

Remove gauge mounting screws and demount gauges

from instrument cluster (Fig. 24).

Fig. 24 Removing Air Pressure Gauges

4.

Separate individual gauges from bracket.

Test

1.

If a suspected gauge has been reading high and does

not return to zero when disconnected, Bourdon tube

has been damaged. Service by replacing with a new

gauge.

2.

If gauge has been reading low or does not read at all,

examine the inlet connection for dirt which might

restrict air from entering gauge. Make a trial

connection and if gauge still does not register correctly,

replace gauge.

IMPORTANT

Always make a comparison test with a gauge

known to be reading correctly before discarding

a questionable gauge.

Install

Installation of air gauges is the reverse of removal

procedure. Be sure to use non-hardening sealing compound on

fitting threads to prevent leaks. Check installation so as to

prevent kinks in air lines.

VOLTMETER

The voltmeter or battery-charging system gauge (Fig.

25) indicates the condition of battery and charging system.

This gauge will monitor a voltage range between 10 and 16

volts. Color segments of this range also indicate system

condition as follows:

GREEN - A well charged battery.

FIRE ORANGE - Either a too high or too low charged

battery.

With key switch "on" but before starting engine, the

voltmeter will show condition of battery. While starting engine,

indicator will temporarily descend to "Fire Orange" segment but

immediately return to "Green" segment when engine is

operating. With engine running at operating speeds, the

voltmeter indicator should remain in the "Green" segment. This

is charging system's normal operating range and indicates

alternator is charging.

If indicator ascends to "Fire Orange" segment, alternator

voltage output is too high.

Constant reading in either high or low fire orange

segments of the voltmeter indicates a

CTS-2735R Page 14

PRINTED IN UNITED STATES OF AMERICA

|