|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

IMPORTANT

Sometimes sealant or dirt on threads of sender

(thermister) prevent a good electrical contact

necessary for sender grounding. Check for this

condition before replacing sender.

If results of Steps 3 thru 5 are unsatisfactory check

continuity of circuit with a standard test light. If continuity is OK

and gauge still does not respond, replace gauge.

OIL PRESSURE GAUGE

The oil pressure gauge is electrically actuated and

consists of two basic components--the instrument cluster

mounted gauge and the engine oil gallery mounted sending

unit. The sending unit: senses the pressure of oil in the engine

oil gallery during engine operation and registers the pressure on

the gauge.

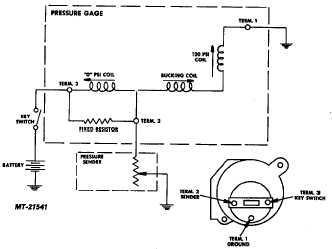

The operation of the oil pressure gauge system (Fig. 21)

is the same as for fuel level gauge except that sender is a

diaphragm unit in oil gallery instead of a float.

Testing for a defective oil pressure system component is

also the same. See FUEL LEVEL GAUGE for testing

procedure.

Fig. 21 Oil Pressure Gauge Circuit Diagram

OIL PRESSURE WARNING LAMP

A second or back-up oil pressure warning system is also

used. This system uses a second oil pressure warning switch

mounted on the engine.

When engine oil pressure is in its normal operating range

(high) the pressure switch is held in its off position and no

current is sent to warning light in the instrument cluster.

When engine oil pressure is below its normal operating

range (low) the pressure switch will close to its "on" position and

deliver current to warning light in instrument cluster and cause

warning lamp to light. OPTIONAL TEMPERATURE GAUGE

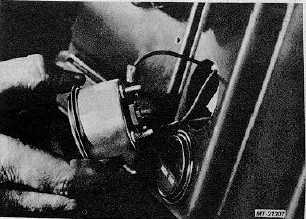

The optional temperature gauges (Fig. 22) are also

electro-magnetic type and are actuated by sending units

(variable resistance thermisters). Sending units are located in

the component on which temperature monitoring is desired

(engine, transmission, rear axles, etc. )

Operating and testing of optional temperature gauges is

the same as for comparable temperature systems previously

covered. See SPECIFICATIONS for variable resistance value

(ohms) required for checking these gauges.

Fig. 22 Servicing Optional Gauge

AIR PRESSURE GAUGE

The air pressure gauges are the mechanical type and

operate on the Bourdon tube principle.

When air system is pressurized, air enters the air

pressure gauge and exerts pressure on the Bourdon tube. As

pressure increases, the Bourdon tube tends to straighten out

and thus actuate the sector and pinion gear (Fig. 23) to which it

is attached. This causes indicator to move across dial in an

upscale direction. When pressure decreases, the Bourdon tube

relaxes and pointer moves in a downscale direction. A steadily

applied air pressure holds the Bourdon tube and pointer at a

fixed

scale

reading

corresponding

to

applied

pressure.

CTS-2735R Page 13

PRINTED IN UNITED STATES OF AMERICA

|