|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

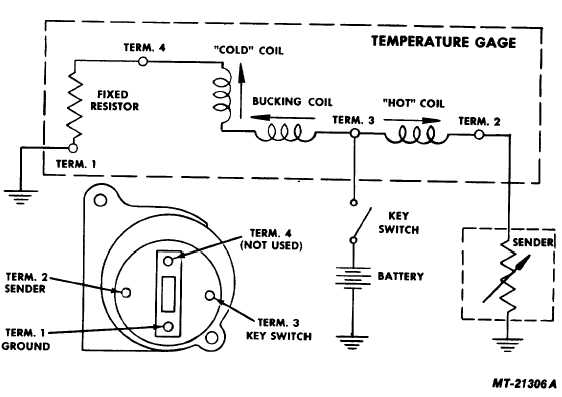

Fig. 20 Water Temperature Gauge Circuit Diagram

temperature coefficient. The decrease in sender resistance

increases the current flowing in the "hot" coil, reaching a

maximum at the full-scale temperature. With maximum current

in the "hot" coil, the pointer and armature assembly will align

itself with the resultant magnetic field produced by the three

coils at the full-scale position. Thus, the interaction of the

magnetic fields of the three coils produces a resultant magnetic

field which controls the rotation and position of the armature

and pointer assembly.

IMPORTANT

The gauge is grounded to chassis through the

ground

terminal

when

plugged

into

the

instrument cluster printed circuit.

The sender terminal is the first terminal clockwise from

ground terminal (when viewed from back side). The ignition

terminal is directly opposite from sender terminal.

Check for faulty components as follows:

1.

Disconnect sender wire at sender (Fig. 20).

2.

Connect one lead of SE-2781 Gauge Tester to sender

wire and the other lead to a good ground.

3.

Set the gauge tester for 55 ohms (left knob at "50" and

right knob at "5"). Turn key switch on and. gauge

should read at full scale. (Pointer within 2 pointer

widths of hash mark).

4.

Set gauge tester for 113 ohms (left knob at 100 and

right knob at 13 ohms). Gauge should read at half

scale. (Pointer within 2 pointer widths of hash mark).

5.

Set gauge tester for 1365 ohms (center knob at "1365"

and other knobs at "O"). The gauge should now read

at low scale. (Pointer within 2 pointer widths of hash

mark).

If results of Steps 3 thru 5 are satisfactory gauge is OK

and sender must be replaced.

CTS-2735R Page 12

PRINTED IN UNITED STATES OF AMERICA

|