|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

INSTRUMENTS

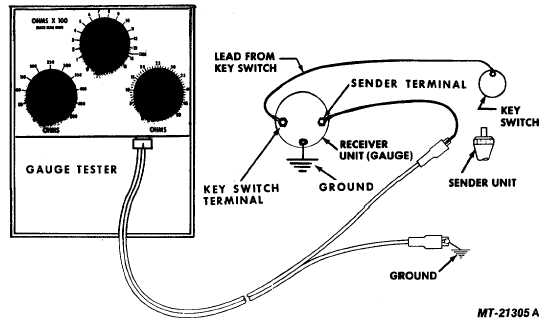

Fig. 19 Checking Fuel Level Gauge System with Gauge Tester

Test for faulty component as follows.

1.

Disconnect wire at tank sender unit (Fig. 19).

2.

Connect one lead of SE-2781 Gauge Tester to end of

sender unit wire and second lead to ground (tester

substitutes for sender unit).

3.

Turn key switch "on".

4.

Set gauge tester for 88 ohms (left hand control knob to

"50" and right hand knob at "38"). Fuel gauge should

read slightly above "full". (Pointer within ball).

5.

Next set left hand knob at "0" and right hand knob at

"44". Fuel gauge should read at "1/2" mark. (Pointer

within ball).

6.

Finally set left hand knob at "0" and right hand knob at

"1". Gauge should now read "empty". (Pointer within

ball).

If fuel gauge reads properly, gauge and wiring between

gauge and sender is OK and trouble is in sender grounding or

sender itself. Replace float assembly if proper grounding does

not correct the problem.

If fuel gauge does not read properly, check continuity of

circuit with standard test light (Fig. 12). If continuity is OK and

gauge still does not respond, replace gauge.

WATER TEMPERATURE GAUGE

The water temperature gauge system consists of two

basic components--the instrument cluster gauge and the

thermister sending unit. The gauge indicates water temperature

while the sender controls the gauge reading. The two units are

connected electrically as shown in Fig. 20.

The operating principle of the temperature indicating

system can be understood by reference to the temperature gage

circuit diagram (Fig. 20). With the ignition switch closed,

current will flow from the battery through the bucking and "cold"

coils and the fixed resistor to ground, and through the "Hot" coil

and the variable resistance temperature sender to ground.

The temperature sender consists of a thermistor

enclosed in a sealed threaded shell containing a heat transfer

medium and equipped with an insulated terminal. With the

temperature sender immersed in a cold liquid (1000F), its

resistance is high and the current flowing through the "hot" coil

is small; therefore, the magnetic field produced by the "hot" coil

is negligible. At this time the pointer and armature assembly

will align itself with the resultant magnetic field produced by the

"cold" and bucking coils at the 1000 F position. The magnetic

field of the "cold" and bucking coils is always a constant and

serves as a reference. As the temperature of the liquid

increases, the resistance of the sender decreases since the

thermistor has a negative temperature

CTS-2735R Page 11

PRINTED IN UNITED STATES OF AMERICA

|