|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FUEL SYSTEM

DESCRIPTION

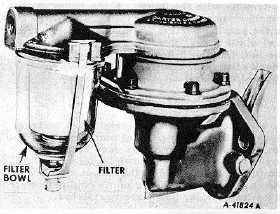

The fuel pumps used on most gasoline type engines

are of the mechanical type and are mounted on the engine,

Fig. 1. The suction side of the pump is connected to the fuel

tank and the discharge side is connected to the carburetor by

tubing designed to carry the fuel. The purpose of the pump

used on gasoline type engines is to suck fuel from the supply

tank and push it into the carburetor float bowl as required by

the engine.

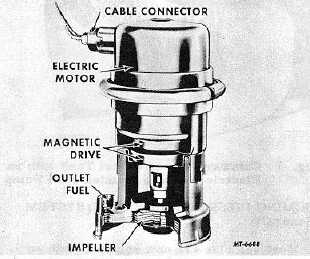

Electric fuel pumps are also used to supply the fuel

from the tank to the engine. In most cases the electric fuel

pump is located in the fuel tank, Fig. 2.

Fig. 1 Mechanical Fuel Pump (Side Mounted Bowl Type)

Fig. 2 In-Tank Mounted Electric Fuel Pump

OPERATION

Mechanical Fuel Pump

In general the pumping operation for all mechanical

pumps is accomplished through a pump rocker arm which

contacts a special cam on the engine camshaft. The rocker

arm in turn actuates a diaphragm in the pump, and this

action, together with the action of inlet and outlet valves in the

pump, causes gasoline to flow through the pump. Pumping

action is controlled, however, by fuel pressure in the pump

outlet line. When the float needle valve in the carburetor is

not seated and the fuel passage into the carburetor float

chamber is open, gasoline will flow to the carburetor. When

the needle valve is closed and held in place by the pressure of

the fuel in the bowl and on the float, the pump will continue to

build up pressure until it overcomes the pressure of the pump

diaphragm spring. This pressure results in almost complete

stoppage of diaphragm movement until further fuel is needed.

Electric Fuel Pump (In-Tank Mounted)

The in-tank mounted electric fuel pump is cushioned

in neoprene to dampen vibrations and is supported by an

adjustable hanger assembly, which makes it adaptable to all

IH fuel tank depths. A spring-loaded latch permits easy motor

replacement. Electrical connections are the sealed quick-

disconnect type, Fig. 2.

MAINTENANCE

Efficient operation of the fuel pump depends on the

proper maintenance of the fuel filter. For this reason the filter

should be checked from time to time to note any accumulation

of dirt, water, or other foreign objects. The interval for actual

cleaning or replacing of the filter element is dependent on

engine operating conditions.

Engines which are equipped with in-tank mounted

electric fuel pump are either equipped with one or two fuel

filters in the system, depending upon the type of engine.

Gasoline type engines are equipped with an in-line fuel filter.

A primary and secondary fuel filter are both used on diesel

engine applications. The primary filter is the first filter in the

line from the fuel tank. The secondary fuel filter is usually

located on the engine.

To clean the wire screen: disc type filter, remove the

filter bowl and filter and wash these parts in a commercial

carburetor clean-

CTS-2050-F

Page 3

PRINTED IN UNITED STATES OF AMERICA

|