|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

FUEL SYSTEM

ing solvent. Blow dry with compressed air. In some cases

where the paper filter -s used, it is advisable to simply replace

the filter. This is particularly true where fuel additives are

used. Such additives can become trapped in filters, and their

accumulation may cause a restriction in flow. Restricted

filters are usually slippery to the touch.

When reinstalling the fuel filter and bowl always

make sure the gasket and spring are in place and that the

retainer screw is tight enough to prevent leakage. A leak at

the gasket will cause erratic action of the pump and thus

retard fuel delivery to the carburetor.

REPAIR OR REPLACEMENT

If it has been determined that fuel system troubles

are being caused by a faulty fuel pump, then the pump can

either be repaired or replaced. Instructions on the different

types of fuel pumps are covered in subsequent paragraphs.

If fuel trouble is encountered on any chassis having

an electric fuel pump, Fig. 2, and the pump is suspected,

check the pump as follows: Disconnect the fuel line at the

carburetor or transfer pump and turn on the ignition switch. If

ample fuel flows, you do not have pump trouble. If the pump

races but fuel does not flow in sufficient volume, the cause is

an air leak in the suction portion of the fuel system (no fuel).

If fuel does not flow at all, inspect the fuel lines or filters for

restrictions or check the electrical connections for a shorted or

open circuit. If all is in order and the pump still does not

operate, remove the pump and replace.

INSTALLATION

Mechanical Fuel Pump

Be sure to use a new mounting gasket between the

mechanical fuel pump mounting flange and the pad on the

crankcase when mounting the pump on the engine. Tighten

the capscrews securely.

Connect the fuel lines, first making sure that there is

no dirt on the fittings which might be drawn into the system.

If the carburetor has not been removed, there will

usually be sufficient fuel in it to run the engine long enough to

fill the fuel pump filter bowl. If there is an air leak between the

filter bowl and gasket, the pump cannot draw fuel into the

bowl. To remedy this, install a new gasket and see that the

bowl seats squarely. Tighten the retainer screw securely with

the fingers only.

If the fuel pump bowl still does not fill, the trouble

may be due to an air-bound condition. In this case, the bowl

should be loosened slightly so that the air can escape, and by

blowing in the gasoline tank filler neck, fuel will be forced into

the pump. Then tighten the bowl securely and start the

engine.

Electrical Fuel Pump (In-Tank Mounted)

(Gasoline Engines)

Connect the fuel lines, first making sure that there is no dirt on

the fittings which might be drawn into the system.

After the pump is installed and fuel and electrical

connections are made, turn on the ignition switch. If ample

fuel flows, there is no trouble with the pump. If the pump

races but there is no fuel flow, there is an air leak in the

suction portion of the fuel system or no fuel in the tank. If no

fuel flows at all, inspect the fuel lines or filters for restrictions

or check electrical connections for open or shorted circuits.

(Diesel Engines)

For the most part the installation instructions for the

electrical fuel pump used on diesel engines is the same as

used on gasoline engines, except that air can be introduced to

the fuel system even on the output side of the pump, since the

transfer pump could suck air if a filter or fuel line were

restricted.

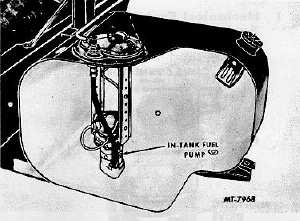

Fig. 3 Cutaway View of a Fuel Tank with an

Electric In-Tank Mounted Fuel Pump

PRIMING DIESEL ENGINE FUEL SYSTEM (General)

Most vehicles are now equipped with an electric

primer switch which is located on the instrument panel and is

used to purge air from the fuel system.

CTS-2050-F

Page 4

PRINTED IN UNITED STATES OF AMERICA

|