|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

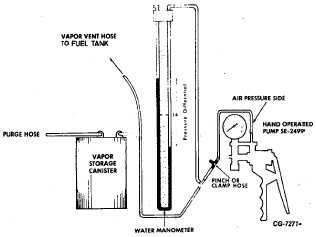

Fig. 18 Method of Pressurizing Vapor Vent System to Check

for Leakage

Pressure test fuel tank vapor vent system by

disconnecting the hose on canister leading to fuel tank and

connect water manometer (SE-2217 or equivalent) and the air

pressure side of hand operated vacuum pump (SE-2499) as

shown in Figure 18.

Place sufficient water in manometer to allow 356mm

(14") differential in height. Pump the hand operated air pump

until a pressure of 356mm (14") of water is applied to the

system (indicated on the manometer). Pinch or clamp hose

between tee and air pump to keep system pressurized.

Observe manometer. If pressure drops more than 51mm (2")

of water in five (5) minutes, an excessive leak is indicated.

On a warm day it is possible to observe a pressure

rise due to evaporation of fuel. This indicates that system is

tight.

If excessive leakage is indicated, first check fuel tank

cap for a loose fit on tank filler neck or a damaged cap

gasket. If either of these conditions are found, replace cap. If

cap-to-filler neck fit and cap gasket are satisfactory, cover

relief valve opening in cap (small hole in portion of cap which

enters filler neck) securely with tape. Reinstall cap and again

pressurize system and check for leakage. If excessive

leakage persists, check all connections in fuel supply and

vapor vent system with soap suds solution to locate leaks.

Inspect for cracked or damaged fuel supply or vapor vent

tubes or connecting hoses. If no leaks are found and system

holds pressure with valve opening uncovered, it can be

assumed that relief valve in cap is faulty. Replace cap.

When pressure testing system following installation

of a new fuel tank, it will be necessary to disconnect and plug

fuel system line at fuel pump to prevent air leakage through

fuel pump and carburetor.

Air Cleaner Charcoal Rings

When engine is shut-off, gasoline vapors released

through the carburetor throats are temporarily trapped in

charcoal rings located in the bottom of the air cleaner. When

the engine is started the vapors are drawn from the charcoal

rings into the engine and burned. Damaged charcoal rings

should be replaced and installed with a silicone type adhesive.

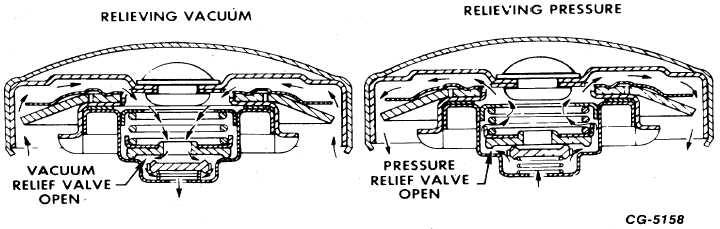

Fuel Tank Cap

Fuel tank caps are nonvented to prevent passing of

gasoline vapors directly into the atmosphere.

Fig. 19 Fuel Tank Cap Relief Valve Operation

CGES-215 Page 13

PRINTED IN UNITED STATES OF AMERICA

|