|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

It is important that canister hoses be connected to

the proper manifold fitting.

Canister Control Valve Test

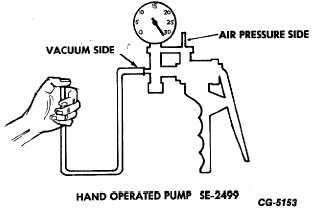

Before starting the following test with hand operated

vacuum pump (SE-2499), check pump for leakage (Fig. 14)

by placing a finger over the vacuum port and pump until full or

near full scale is reached. Watch pump gauge. If vacuum

drops rapidly, pump is leaking and should not be used for

test. If a very slow leak is indicated, the pump may be used if

the degree of pump leakage is kept in mind.

Fig. 14 Check Hand Operated Vacuum Pump SE-2499 for

Leakage

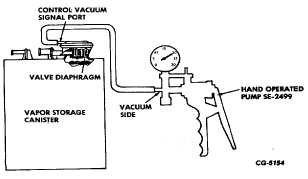

1.

Test canister fuel bowl vent control valve diaphragm

by applying vacuum to the control valve port (smaller top port

valve assembly) with hand operated vacuum pump (SE-

2499). Observe vacuum pump gauge (Fig. 15). If vacuum

drops rapidly the control valve diaphragm is leaking and the

canister must be replaced.

Fig. 15 Canister Fuel Bowl Vent Control Valve Diaphragm

Test

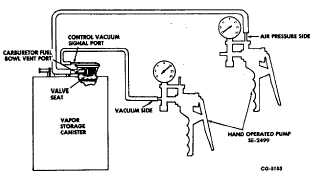

2.

The valve seat portion of the fuel bowl vent control

valve can be tested by applying vacuum to the

control valve (same as diaphragm test Fig. 15) and

at the same time (with another hand operated pump

SE-2499 using air pressure side of pump) apply air

pressure to the valve (Fig. 16) until pressure buildup

is felt. If pressure buildup is not felt the valve seat is

leaking and the canister must be replaced.

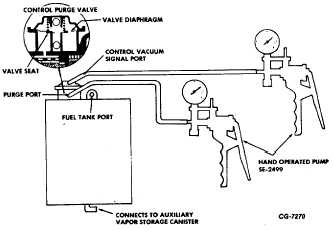

3.

Test purge control valve diaphragm and valve seat

by applying vacuum with hand operated vacuum

pump (SE1499) simultaneously to both vacuum

signal port and purge port (see Fig. 17). If vacuum

of either pump drops rapidly the valve is faulty and

the canister must be replaced.

Fig. 16 Canister Fuel Bowl Vent Control Valve Seat Test

Fig. 17 Canister Purge Control Valve Diaphragm and Valve

Seat Test

CGES-215 Page 12

PRINTED IN UNITED STATES OF AMERICA

|