|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

TROUBLE SHOOTING

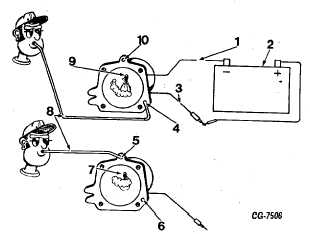

5. Apply battery voltage to solenoid valve side of cable

as shown. The solenoid valve should make a slight

noise or movement felt when current is applied and

released indicating the solenoid valve plunger is

operating.

a.

If the solenoid is operating properly, proceed to step

6.

Figure 68. Step 6

1. To Solenoid Valve Case

6.

“A” Port Closed

2. Battery, 12 Volt

7.

Air Output

3. Solenoid Cable

8.

Use Vacuum Hose for Air

4. “A” Port Open

Input Test

5. “B” Port Open

9.

Air Output 10. “B” Port

Closed

b. If the noise is not heard or movement felt,

remove solenoid valve and cover assembly

from carburetor. Make a resistance check

with an ohmmeter from the solenoid valve

cable to the valve assembly case as shown.

The ohmmeter should read approximately 50

+ 10 ohms. If resistance is zero or a very high

reading, the solenoid valve assembly must be

replaced.

c. If resistance is 50 + 10 ohms, the solenoid

valve windings are good. Remove solenoid

valve from cover. Check to see if valve seat is

sticking, keeping solenoid valve plunger from

operating.

6. If Steps 1 through 5 have proved that the electrical

portion of governor system is operating properly, the

trouble must be in the cover vacuum passages on

the carburetor.

a. With solenoid valve assembled to cover, apply air

through a small diameter hose as shown to port

“A,” then port “B” to insure passages are clear.

With battery voltage applied: Port “B” should be

closed. Port “A” should be open. Without battery

voltage applied: Port “B” should be open. Port “A”

should be closed.

b. If solenoid valve plunger is not seating properly,

replace solenoid valve.

c. If vacuum passages in the cover are clogged,

clean (cover only) with commercial carburetor

cleaning solvent.

7.

Some carburetor malfunctions that are not a part of the

EVM governor system may affect governor action. These

malfunctions can be corrected by using the CLEANING

AND INSPECTION portion of this service manual.

SECONDARY CONTROL VALVE TROUBLE SHOOTING

Malfunction of the secondary control valve can cause

fluctuation of engine speed (“surging”) when the governor is in

effect or failure of the governor to limit engine speed.

Because calibration of the control valve requires special

equipment, the secondary diaphragm cover (with secondary

control valve) is assembled, calibrated and sealed at the factory

and furnished for service only as an assembly. Control valve

components are not serviced separately.

Outlined in the following paragraphs are procedures for

testing the secondary control valve. These procedures are used to

determine if the control valve is satisfactory or if it should be

replaced.

Bench Test

The following “bench” test procedure can be used to

check functioning of the control valve. It is recommended that this

check be made at the time of carburetor overhaul or if improper

valve operation is suspected.

1. Connect a controllable vacuum source to the vacuum

inlet of the control valve diaphragm chamber, as shown in

Fig. 69. (Distributor tester SE-1925 or SE-1979 can be

used as a vacuum source.) Apply 6 inches of vacuum

CGES-125-T Page 43

PRINTED IN UNITED STATES OF AMERICA

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

TROUBLE SHOOTING

to the diaphragm chamber. If vacuum holds, the control valve

diaphragm is satisfactory. If vacuum cannot be maintained,

|