|

| |

diaphragm is faulty and the complete secondary diaphragm

assembly should be replaced.

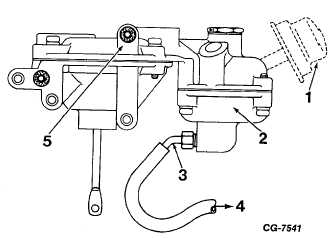

Figure 69 Vacuum Connection for Checking Secondary Control

Valve Diaphragm

1. Air Filter (Where Used)

4.

To Vacuum Source (6” G)

2. Diaphragm Chamber

5.

Not Used When Air Filter

3. Adapter Fitting

is Used

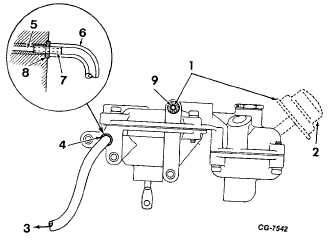

2. Connect the vacuum source to the venturi vacuum

pickup passage on the back of the cover assembly, as

shown in Fig. 70. Tightly cover the fresh air passage

also on the back of the cover assembly. Apply 6 inches

of

vacuum.

If

secondary

diaphragm

moves

(compresses spring) and vacuum holds, secondary

diaphragm is satisfactory. If diaphragm does not move

or if vacuum cannot be maintained, secondary

diaphragm is faulty P-d should be replaced.

3. With vacuum applied as in Step 2, uncover the fresh air

passage. If vacuum holds, control valve needle and

seat are satisfactory. If vacuum cannot be maintained,

control valve is faulty and the complete secondary

diaphragm assembly should be replaced.

On the Vehicle Test

The “on the vehicle” test outlined below can be used to

help locate the cause for loss of governor control.

1. With the vehicle on the service floor accelerate the

engine to check governor operation.

a. Governor should limit engine speed to 150-250 initial

overrun. Adjust governor if necessary.

Figure 70 Vacuum Connection for Checking Secondary

Control Valve and Diaphragm

1.

To Check Diaphragm Cover Passage

To Check Needle and Seat Uncover Passage

2. Air Filter

6. Hose .125 I.D.

(Where Used)

7. Tube .125 O.D.

3.

To Vacuum Source

8. Gasket

(6” HG)

9. Fresh Air Passage

4.

Venturi Vacuum Passage

5.

Vacuum Passage

NOTE:

Initial

overrun

means

that

under

acceleration the engine will momentarily exceed

governed speed by approximately 150-250 RPM

and then settle to governed speed.

b. If there is no governor control, proceed with

Step No. 2 below.

c. If the engine governs at light load and does

not govern at wideopen throttle, the problem is

probably in the secondary control valve.

Proceed with Step No. 4 below.

2. Disconnect the vacuum line (distributor to governor

throttle actuating unit) from the fitting at the governor

unit. Leave the secondary control valve vacuum line

connected. Operate the engine at 2200 RPM, wet

your finger and hold it over the opening in the fitting.

If the engine speed slows to approximately 1000

RPM, the governor trouble is in the governor control

(“spinner”) valve or the lines or connections to the

governor control valve. If the engine does not slow

down, proceed with Step No. 3.

CGES-125-T Page 44

PRINTED IN UNITED STATES OF AMERICA

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

TROUBLE SHOOTING

3. Disconnect the secondary control valve vacuum line

from the fitting and remove the fitting. Again,

operate the engine at 2200 RPM and place a wet

finger over the vacuum passage in the governor

throttle

unit.

If

the

engine

now

slows

to

approximately 1000 RPM, the problem is in the

secondary control valve or its vacuum line. If the

engine does not slow down, the problem is in the

governor throttle unit or the vacuum passages behind

it.

4. When the problem is suspected to be in the

secondary control valve, operate the vehicle on the

|