|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ADJUSTMENT PROCEDURE

NOTE: Record the number of turns it takes

to increase or decrease the engine RPM to

the specified speed shown:

V-392

2000 RPM

MV-404, 446

2400 RPM

V-537, 605

2000 RPM

4. Run curb idle stop screw in until it contact the internal

stop.

5. Release choke as it opens completely.

6. Start engine, observe and record (RPM) tachometer

reading. If RPM reading does not correspond with fast idle

speed specification chart, an adjustment should be made.

7. To increase RPM, continue to turn the curb idle screw until

proper fast idle speed is reached (See Fig. 53).

8. Before shutting off engine back out curb idle screw until

engine speed is reduced to curb idle speed to prevent engine

dieseling. Shut off engine (See Fig. 42).

9. Depress accelerator pedal to floor. Close choke and

release accelerator pedal.

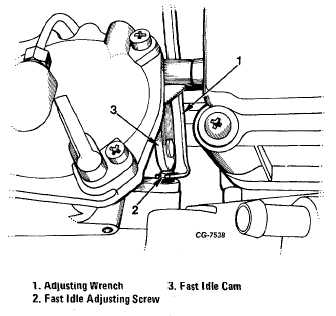

Figure 54 Adjusting Fast Idle Screw With SE-1772-18

Wrench

10. Reset curb idle screw until it lightly contacts the inner

stop. Turn the idle screw in the number of additional turns

recorded (in Step 8) to reach proper fast idle speed setting.

11. Adjust fast idle screw with special wrench SE-1772-18

until the screw just contacts the fast idle cam (See Fig. 54).

Contact is established when visual clearance between the

screw and the cam is eliminated or when the throttle lever

starts to move.

12. To recheck adjustment, choke closed, back out idle screw

two turns and then reset screw until lightly contacting internal

stop.

13. Open choke, start engine, proper engine RPM should now

be obtained.

14. Repeat Step No. 9.

15. Reinstall spring on idle speed screw and install screw

with spring.

16. Reinstall air cleaner and adjust proper curb idle speed

(See Specifications).

Idle Speed and Fuel Mixture Adjustment Procedure Without

Exhaust Analyzer (Speed Drop Method)

1. Connect tachometer to engine (Tachometer should have

expanded scale of 400-800 RPM or 0-1000 RPM and 1%-2%

accuracy.)

2. Turn idle mixture screw(s) "out" (counterclockwise) against

tab stop.

NOTE: If working with a unit rebuild which

has not had the idle limiter caps installed,

refer to specification for the initial idle

setting.

3. Operate engine until thoroughly warmed up.

4. Adjust idle speed screw to give engine speed higher than

specified idle speed. (See "Specifications".)

5. Turn idle mixture screws "in" (clockwise) slowly and

equally until specified idle speed is obtained. The resulting

idle fuel mixture is optimum for exhaust emission control.

NOTE: If working with unit rebuild, install

idle limiter caps at this time.

6. If engine runs rough after obtaining specified idle speed or

if specified idle speed cannot be obtained (per Steps 4 and 5),

it will be necessary to remove the idle limiter caps and

establish proper mixture screw setting as follows:

a. Remove limiter caps. To prevent damaging screw threads

or seat, file or grind away the side of the cap. Do not pry cap

off.

b. With engine operating, adjust mixture screws to obtain

"lean best idle" at the specified idle speed. ("Lean best idle" is

the point at which engine speed drops approximately 10 RPM

due to leanness.)

CGES-125-T Page 36

PRINTED IN UNITED STATES OF AMERICA

|