|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ADJUSTMENT PROCEDURE

If the fuel level is too high or low, install the sight plug, drain

the fuel bowl by loosening one lower retaining bolt from the

fuel bowl and drain the fuel into a suitable container. Install

the bolt and the fuel level sight plug and start the engine to fill

the fuel bowl. Check the fuel level again before altering the

float setting. This will eliminate the possibility of foreign

material causing a temporary flooding condition.

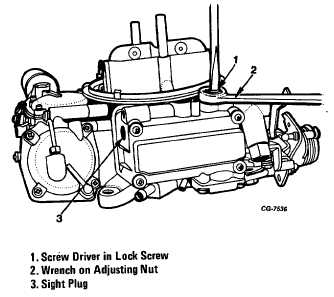

If the fuel level is still high or low, loosen the lock screw on the

top of the fuel inlet seat and turn the adjusting nut in or out to

correct the fuel level. 1/6 turn of the adjusting nut equals

approximately 3/64" in fuel level. Remove the sight plug and

recheck the fuel level. Repeat the foregoing procedure until

the correct fuel level is obtained.

Figure 52 Adjusting Fuel Level

It is important that the fuel level be maintained to

specifications, as the fuel level is a part of the carburetor

calibration.

CAUTION:

Do not loosen the lock screw or attempt to

adjust the fuel level with the sight plug

removed and the engine running, as this

creates a fire hazard.

Fast Idle Adjustment

Idle speed and fuel mixture settings must be made with the

engine at normal operating temperature, parking brake

applied

and

choke

open.

See

"Specifications"

for

transmission shift selector position and air conditioner switch

settings.

When making carburetor adjustments, disconnect vacuum

hose from vapor storage canister and plug end of hose. After

idle adjustments have been made, remove plug and reconnect

hose to canister. To compensate for fuel and temperature

variations

when

setting

idle

mixture,

observe

these

precautions:

a. Do not idle engine continuously for more than three

minutes at one time.

b. After each three minutes of idling increase engine speed to

2000 RPM for one minute.

c. Continue with idle adjustment procedure. Do not idle

engine for more than three minutes without repeating Step "b".

It is imperative that the precautions outlined above be

followed on engines equipped with road speed controlled

spark advance systems where extended idling could permit

sufficient increase in engine coolant temperature to activate

high temperature vacuum control valve and thereby affect

engine timing and idle speed.

Fast idle adjustment is performed as follows:

1. Shut off engine, remove air cleaner, connect tachometer of

known accuracy.

2. Depress accelerator pedal to floor. Close choke and

release accelerator pedal.

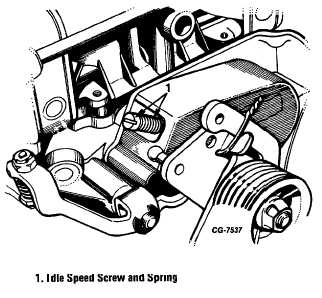

3. Remove curb idle stop screw and spring, reinstall idle

stop screw without spring (See Fig. 53).

Figure 53 Curb Idle Speed Screw and Spring

CGES-125-T Page 35

PRINTED IN UNITED STATES OF AMERICA

|