|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ADJUSTMENT PROCEDURE

INSTALLATION AND ADJUSTMENTS

Off Engine Fast Idle Adjustment

If the carburetor was removed from the truck for replacement

or overhaul procedures, it is recommended that a preliminary

fast idle adjustment be performed as follows.

1. After carburetor is completely assembled open throttle with

throttle lever and close the choke plate.

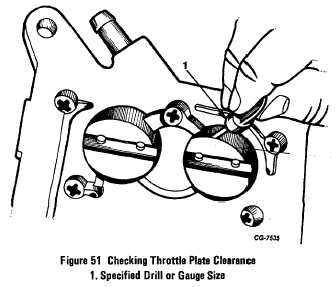

2. Invert carburetor. Insert gauge (from gauge set SE-2425

or drill of same diameter) upstream between throttle plate and

throttle body of the primary bore (see Fig. 51).

Figure 51 Checking Throttle Plate Clearance

Fast Idle Throttle Plate Clearance

Engine Speed

(Gauge or Drill Sizes)

V-392 2000 RPM

.040

MV-404 2400 RPM

.045

MV-446 2400 RPM

.045

V-537 2000 RPM

.045

V-605 2000 RPM

.045

3. With gauge or drill held in place by the primary throttle

plate against the bore, adjust the fast idle screw until the

screw touches the cam lightly (see Fig. 54).

4. The gauge-or drill size dimension for the throttle plate

clearance and fast idle speed are given above:

5. After the carburetor is installed on the engine, warm

engine to operating temperature, connect tachometer and

check fast idle reading with above specifications.

Installing Carburetor on Engine

Always make a thorough inspection of the carburetor before

installing on the engine. Operate the choke and throttle levers

to be sure choke and throttle plates function properly. Make

sure unit is clean and undamaged in any way. Mating surface

of intake manifold must also be <-f clean and free of burrs

or damage. Use a new flange gasket and secure the

carburetor to the intake manifold with mounting nuts and lock

washers. Do not tighten nuts all the way down. Connect the

fuel line, distributor vacuum line, governor lines (where used)

and throttle and choke linkage. Tighten mounting nuts

alternately and evenly in a criss-cross pattern to compress

flange gasket. Draw nuts down tightly.

Loading the Throttle Redundant Safety Spring

Loading the linkage is accomplished by rotating the throttle

lever to wide open throttle by moving accelerator control rod

to the right. Do not rotate throttle lever directly, since it will

snap to the closed position, then attach throttle return spring

to the trip lever. Secure opposite end of throttle return spring

to throttle return spring anchor bracket. Slowly return throttle

lever to idle position.

CAUTION

Whenever throttle return spring is disconnected at either

end, the throttle linkage at the carburetor will snap to the

closed position with a spring force sufficient to cause

possible personal injury.

ON ENGINE ADJUSTMENTS

Fuel Level Adjustment

Position the truck on a level floor. Be sure the fuel pump

pressure is within specifications. Operate the engine until the

normal, stabilized operating temperature has been reached.

Place a suitable container below the fuel level sight plug to

collect any spill-over of fuel. Check each fuel bowl separately.

With the engine stopped remove the air cleaner assembly,

fuel level sight plug and gasket and check the fuel level (Fig.

52). The fuel level within the bowl should be at the lower edge

of the sight plug opening + 1/32". If the fuel level is

satisfactory, install the sight plug.

CGES-125-T Page 34

PRINTED IN UNITED STATES OF AMERICA

|