|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

coolant directed to the radiator is modulated by the thermostat

that opens the outlet to the radiator and reduces the orifice

size of the coolant bypass. Figure 136.

Secondary cooling systems include the engine oil

cooler, chassis heater and air compressor.

The oil cooler is mounted at the lower left corner of

the crankcase. The coolant flows from the left bank

crankcase water jacket through the cooler and into crankcase

inlet area. The amount of coolant flowing through the cooler

is metered by the diameter of the outlet hole on the oil cooler

housing.

Coolant for the air compressor is tapped off the front

of the cylinder head, left bank, flows through the air

compressor and back into the crankcase coolant inlet casting.

Coolant for the chassis heater is picked up off the

rear of the right cylinder head and returned to the suction side

of the coolant pump.

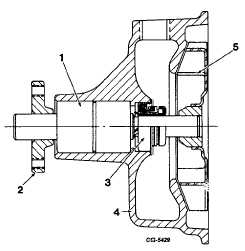

The centrifugal water pump is serviced only as a

complete assembly, Figure 137.

Fig. 137 Section View of Water Pump Assembly

1. Bearing assembly

4. Housing

2. Pulley hub

5. Impeller

3. Seal

Engine Assembly

1.

With the cylinder block attached to the engine repair

stand, turn the block on the stand so the bottom faces

upward. Make sure the drain plugs are installed in the

cylinder block if they have been removed.

2.

Coat the camshaft lobes, bearing surfaces, gears and

bores with engine oil.

3.

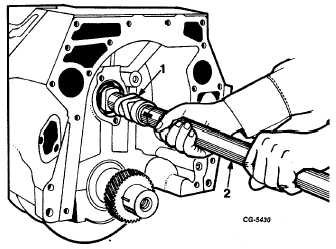

Install camshaft into bore with fuel pump cam, distributor

drive gear, camshaft gear and thrust flange installed on

shaft.

NOTE: If gears and fuel pump cam have been removed,

use SE-1880 installer and SE-1880-2 adapter to install

camshaft, Figure 138. This will help prevent nicking or

other damage to the camshaft bearings. Install

distributor drive gear, fuel pump cam and camshaft gear

as outlined under Camshaft Engine Overhaul.

Fig. 138 Use of SE-1880 Camshaft Installer and SE-188G-2

Adapter

1. Camshaft

2. Installer

4.

Install two bolts and lockwashers in camshaft thrust

flange, working through the holes in the camshaft gear.

See "Torque Chart" for proper torque.

5.

With the use of a dial indicator, check the camshaft end

play, Figure 139. See "Specifications." If-the end play

exceeds the limits, replace the camshaft thrust flange.

CGES-210 Page 56

PRINTED IN UNITED STATES OF AMERICA

|