|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

Oil Pan

The pan should be thoroughly cleaned in cleaning

solvent to remove any foreign material from around the baffle

plate which is spot welded in place. Inspect oil pan for cracks

or deformation and straighten or weld.

Remove all gasket material from the oil pan flange.

Check the oil pan drain plug boss for fit and thread

wear. If the plug is loose or the threads are damaged, repair

the threads or replace the oil pan.

Manifolds

The intake manifold is cast in one piece and supplies

both cylinder banks. It should be cleaned and examined for

cracks or leaks. Warpage of the intake manifold will require

replacement as any attempt to resurface the intake manifold

will create misalignment of the ports to the cylinder heads.

The intake manifold also contains the direction of distributor

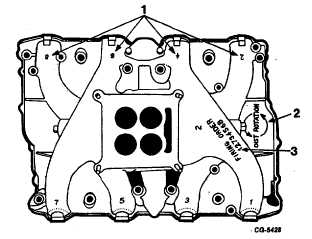

rotation, firing order and the cylinder numbers Figure 135.

Fig. 135 Illustration of Information Contained on Intake

Manifold

1. Cylinder number

2. Direction of distributor rotation

3. Firing order

Each bank has a separate exhaust manifold which

should both be cleaned and examined for cracks or leaks.

Flywheel and Ring Gear

Clean the flywheel and ring gear with a cleaning

solvent, removing all traces of oil and grease. Inspect the

flywheel ring gear. If any teeth are damaged or if the ring

gear

is

loose

on

the

flywheel,

the

ring gear must be replaced. Check the flywheel mounting bolt

holes for wear; also check mounting face of flywheel for

indication of looseness.

To replace the flywheel ring gear, heat the gear with

a torch and remove it from the flywheel with a' hammer and

drift Heat the new ring gear evenly all the way around with a

torch. While the ring gear is hot, install the gear on the

flywheel and allow it to cool.

Water Pump and Coolant Flow

Coolant enters the engine at the lower left hand

corner of the crankcase. The coolant then flows into the water

pump where it is mixed with a quantity of bypassed hot

coolant. The water pump discharges into both the right and

left of the crankcase. The circulation of the coolant is from

front to rear of the crankcase, then flows up into the cylinder

head via three holes. The flow continues forward through the

cylinder head. In flowing through the cylinder head the coolant

is forced through a zig-zag path to insure maximum scrubbing

of critical areas of the cylinder head such as exhaust valve

seats and spark plugs.

The coolant exits the cylinder heads into a common

cavity at the front of the crankcase. Temperature sending unit

is located in this cavity. From this cavity the coolant flows

into the chassis radiator or back into the water pump via a

variable orifice bypass. The amount of

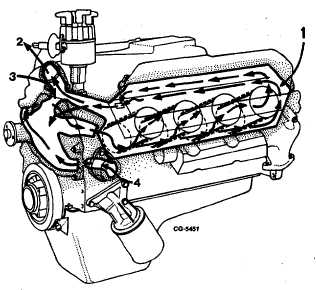

Fig. 136 Coolant Flow Cut-Away

1. Full pressure flow to rear of crankcase-up-and to front of lead.

2. Outlet

3. Bypass

4. Inlet

CGES-210 Page 55

PRINTED IN UNITED STATES OF AMERICA

|