|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

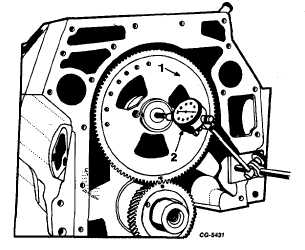

Fig. 139 Checking Camshaft End Play

1. Camshaft gear

2. Dial indicator

6.

Wipe the backs of the cylinder block half of the bearings,

making sure the dirt is removed. Lubricate the block half

of the bearings on both sides with a light film of engine

oil. Place the bearing shell halves in position in the bore

of the cylinder block, making sure the bearing shells are

fully seated, the oil holes in the bearing shells line up with

the oil holes in the cylinder block and the locking tangs on

the bearings fit into the recesses. Follow the same

procedure and place the bearing shell halves in the

bearing caps. Place a film of engine oil on both sides of

the shell surfaces and

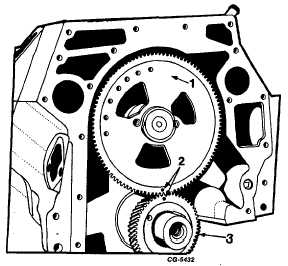

Fig. 140 Aligning Timing Marks on Camshaft and Crank- shaft

Gears

1.

Camshaft gear

2.

Timing marks

3.

Crankshaft gear

install the crankshaft, aligning itself in the bearing while,

at the same time, aligning the timing marks of both the

camshaft and crankshaft gears, Figure 140

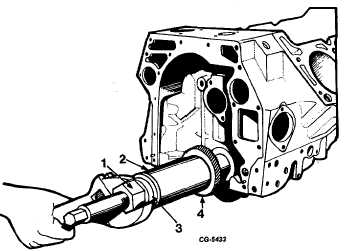

NOTE: If crankshaft gear has been removed, it may be

installed with the crankshaft in the engine using SE-1900

Installer, with SE-1900-18 Adapter and thrust bearing to

reduce friction, Figure 141.

7.

Place the bearing caps and bearing lower halves over the

crankshaft journals. Be sure the bearing caps are

properly installed with the number toward the left side of

the crankcase and the arrow, pointing toward the front of

the engine. Use new selflocking bolts for installing the

bearing caps. Finger tighten the bearing caps. Using a

soft hammer, tap the number 1, 2 and 4 bearing caps

until the rear machined faces of the caps are flush with

the machined faces of the crankcase.

Fig. 141 Installing Crankshaft Gear with SE-1900 Installer and

SE-1900-18 Adapter

1. Nut

3. Thrust bearing

2. Sleeve

4. Gear

Repeat the same operation for bearing cap number 5 only

aligning the front face of the cap with the crankcase. The

number 3 bearing rear thrust flanges must be flush with each

other. Aligning caps in this manner will assure proper cap

location. Check this alignment at both sides (left and right) of

the bearing cap. Torque the bolts to specified torque using a

tension wrench. See "Torque Chart."

CGES-210 Page 57

PRINTED IN UNITED STATES OF AMERICA

|