|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

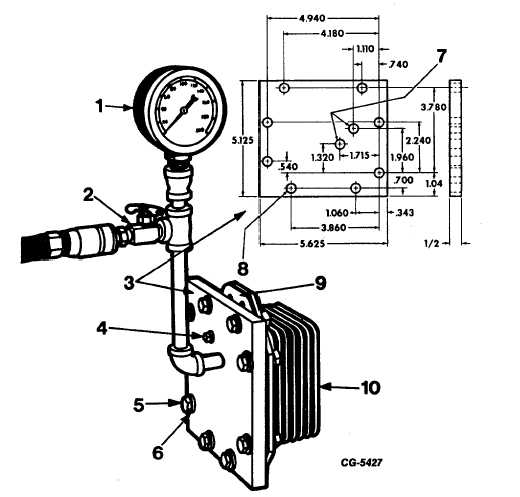

1.

Attach test plate and gasket to core assembly

mounting face flange (Figure 134). The test plate

must be made locally according to the dimensions in

the insert in Figure 134. Obtain engine oil cooler

housing gasket from service parts stock.

NOTE: The oil inlet opening in the cooler core

assembly is located in one of two locations.

Therefore, the test plate must include a tapped

hole for either location to permit applying air

pressure to the core. Install test plate pipe plug

at oil inlet hole not in use.

2.

Install pressure gauge, air control valve and quick

connect air coupler to test plate (Figure 134). Apply

80 to 100 lbs. of air pressurelt6 the core assembly.

3.

Immerse oil cooler core assembly in a container of

water. If a leak is observed, replace core assembly.

CAUTION: Use adequate safety precautions when

preforming pressure test.

Fig. 134 Pressure Testing Engine Oil Cooler Core Assembly

1. Pressure gauge

6. Flat washers - (16 required)

2. Air control valve

7. Drill & tap 1/8 PT THD. this side two holes

3. Test plate (make locally)

8. .375 Dia. - (8 holes)

4. Pipe plug 1/8 NPT

9. Gasket, oil cooler housing IH No. 446647-C1

5. Hex head bolts 5/16 NC x 1% - (8 required)

10. Core assembly, oil cooler

CGES-210 Page 54

PRINTED IN UNITED STATES OF AMERICA

|