|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

ENGINE

5.

Check the pump shaft clearance in the bore. To

correct for wear beyond limits given in specifications,

replace pump assembly.

6.

Check backlash between pump body gears. If this

exceeds the figure shown in the specifications,

replace gears.

7.

Establish body gear end clearance.

NOTE: The oil pump cover gasket controls the

clearance (end play) between the pump body gears

and the pump cover. Add or remove gaskets to

obtain desired clearance. See '"Specifications."

8.

When installing pump gears and shaft, these parts

should be oiled liberally with engine oil for initial

lubrication.

9.

Before installing the relief valve in the pump body,

insure valve is free of burrs and the valve bore is free

of varnish so the valve operates smoothly in its bore.

NOTE: If it becomes necessary to remove burrs from

the valve, insure valve edges are not rounded.

10.

Check relief valve spring for proper tension. See

SPECIFICATIONS.

11.

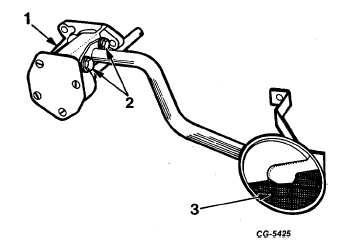

When assembling the screen assembly to the pump

body make sure the gasket is in place. Then tighten

bolts securely, Figure 132.

Fig. 132 Oil Pump and Screen Assembly

1. Oil pump

2. Bolts

3. Screen assembly

Oil Cooler and Filter Base

Figure 133 illustrates an exploded view of the oil

cooler and filter base. Upon engine overhaul, the oil cooler

and filter base, if so equipped, should be disassembled and

the cooler element cleaned in a commercial radiator type

solvent. Then flush the element with clean water until rinse

water runs clear.

Fig. 133 Exploded View of Oil Cooler and Filter Base

1. Filter base

5. O-ring

2. Gaskets

6. Plug

3. Valve

7. Cooler element

4. Spring

8. Cooler body

Check the relief valve spring for proper tension, see

SPECIFICATIONS. Also, check the valve for burrs or

scratches. Small burrs or scratches may be removed with

crocus cloth.

When reassembling the oil cooler, use new gaskets

and tighten the bolts securely.

NOTE: On engines not equipped with the oil

cooler, the filter base should be cleaned and

passages checked clear of restrictions.

Oil Cooler Pressure Test

Where conditions indicate the need for testing the

engine oil cooler core assembly for leaks, the core inlet and

outlet openings must be closed off and the assembly

pressurized. Instructions for pressure testing the oil cooler

core assembly are as follows:

CGES-210 Page 53

PRINTED IN UNITED STATES OF AMERICA

|